Pro . 13, 2024 12:42 Back to list

di dismantling joint

Dismantling Joints An Overview

Dismantling joints, also commonly referred to as dismantling couplings or dismantling flanges, are crucial components used in piping systems. They are essential for the maintenance and repair of pipelines, providing an easy and efficient means to disconnect and reassemble pipe sections without extensive disassembly. This article explores the definition, design features, applications, advantages, and considerations of dismantling joints in various industries.

Definition and Functionality

Dismantling joints are specialized fittings that enable the separation of pipe segments for maintenance, repair, or inspection purposes. They typically consist of a pair of flanged ends connected by an adjustable sleeve. The adjustable sleeve allows for controlled separation and reconnection, which can be particularly useful in areas where space is limited. When maintenance is required, the dismantling joint can be easily loosened, enabling technicians to access the interior of the piping without disassembling the entire system.

Design Features

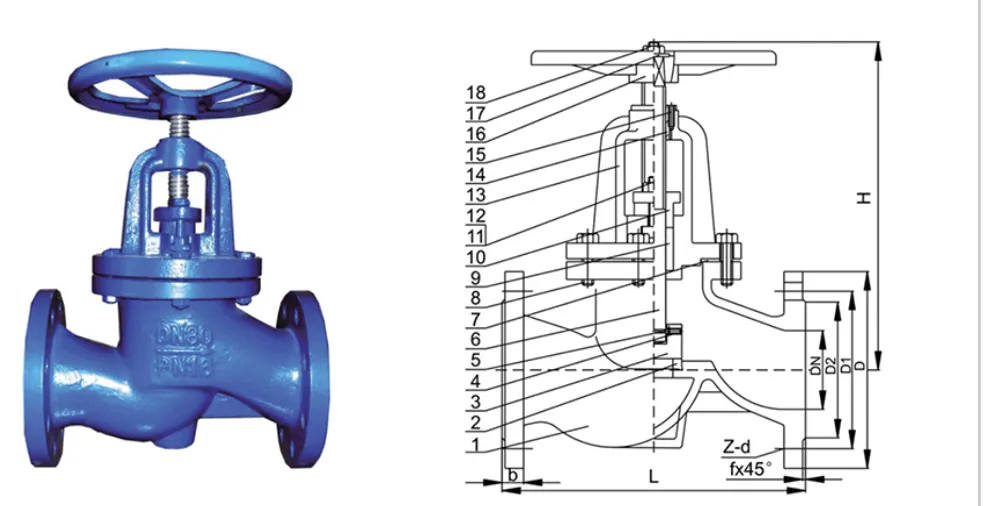

The design of dismantling joints varies, but they generally include

1. Flanged Ends These provide a secure connection to the pipework. The flanges are designed to fit standard pipe sizes, ensuring compatibility with existing systems.

2. Adjustable Sleeve The sleeve can be extended or retracted, allowing for precise spacing adjustments when reconnecting sections. This feature helps accommodate any thermal expansion or shifts in the pipeline.

3. Sealing Mechanism Dismantling joints often incorporate gaskets or O-rings to ensure a tight seal and prevent leakage when the joint is in place.

4. Materials Dismantling joints are typically made from durable materials such as carbon steel, stainless steel, or ductile iron, depending on the application and the medium being transported.

Applications

Dismantling joints are widely used in various industries, including

- Water Supply Systems They allow for easy access to valves, meters, and other critical components of municipal water pipelines for maintenance.

- Wastewater Treatment Facilities These joints facilitate the servicing of sewage systems, enabling quick access for inspections and repairs.

- HVAC Systems In heating, ventilation, and air conditioning systems, dismantling joints provide a flexible connection that can be adjusted during installation or maintenance

.di dismantling joint

- Industrial Processes Many manufacturing processes require complex piping networks. Dismantling joints simplify the management of such systems, ensuring minimal downtime during maintenance.

Advantages

The use of dismantling joints offers several advantages

1. Ease of Maintenance Dismantling joints allow for quick and efficient access to pipeline components, significantly reducing maintenance time and costs.

2. Flexibility The adjustable nature of these joints allows for changes in the layout of the piping system without complete disassembly.

3. Reduced Downtime With the ability to quickly detach pipe sections, operations can resume faster after maintenance or inspections, minimizing productivity loss.

4. Cost-Effectiveness By reducing labor time and minimizing the need for heavy equipment during maintenance, dismantling joints contribute to lower overall operational costs.

Considerations

While dismantling joints provide many benefits, several considerations should be taken into account when selecting and installing them

1. Sizing It’s crucial to select the proper size and type of dismantling joint to match the specifications of the existing piping system.

2. Material Compatibility The selected materials must be compatible with the transported medium to avoid corrosion or degradation.

3. Installation Guidelines Proper installation is critical to ensure seal integrity and prevent leaks. Adhering to manufacturer guidelines is essential.

4. Regular Inspection Like any critical component in a piping system, dismantling joints should be periodically inspected for signs of wear or damage.

Conclusion

Dismantling joints are vital components in modern piping systems, enhancing flexibility and simplifying maintenance efforts. Their design, which includes adjustable sleeves and robust flanged connections, facilitates easier access to pipeline components. As industries continue to evolve and prioritize efficiency, the role of dismantling joints in ensuring reliable and maintainable piping systems will only become more pronounced. Whether in water supply, wastewater treatment, HVAC systems, or industrial processes, dismantling joints represent a smart solution for managing complex piping networks while keeping maintenance practical and cost-effective.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025