Lis . 08, 2024 09:09 Back to list

Understanding Ball Type Foot Valves and Their Applications in Fluid Control Systems

Understanding Ball Type Foot Valves An Essential Component in Fluid Control Systems

In the realm of fluid control systems, various forms of valves play crucial roles in ensuring the efficient and safe transport of liquids and gases. Among these devices, the ball type foot valve stands out due to its design, functionality, and applications. This article delves into the characteristics, advantages, and applications of ball type foot valves, providing a comprehensive understanding of this vital component.

What is a Ball Type Foot Valve?

A foot valve is a one-way valve typically installed at the bottom of a suction pipe in a pump system. Its primary function is to prevent backflow or reverse flow of fluids when a pump is not in operation. The ball type foot valve, as the name suggests, employs a spherical ball as its closing mechanism. This design allows the ball to move freely within the valve seat, ensuring that the valve opens and closes effectively, providing a reliable operation.

Design and Functionality

The ball type foot valve consists of several key components the valve body, ball, seat, and spring (in some designs). The valve body is usually constructed from durable materials such as brass, stainless steel, or PVC, which provide resistance to corrosion and wear. The ball, which is typically made of plastic or metal, is positioned in the valve body and serves as the primary mechanism for sealing off the flow.

When the pump operates, the pressure from the suction pipe forces the ball upward, allowing fluid to flow through the valve. Conversely, when the pump shuts down, gravity and fluid pressure push the ball down against the seat, creating a tight seal that prevents backflow. This simple yet effective mechanism ensures that the pump maintains its prime and operates efficiently whenever needed.

Advantages of Ball Type Foot Valves

1. Prevention of Backflow One of the primary advantages of the ball type foot valve is its ability to prevent backflow. This feature is crucial in applications where maintaining the fluid level in the pump is necessary for optimal performance.

ball type foot valve

2. Easy Installation and Maintenance Ball type foot valves are generally easy to install and require minimal maintenance. Their straightforward design means that routine inspections and occasional replacements can be performed without extensive downtime.

3. Versatile Applications These valves are highly versatile and can be used in various applications, including agricultural, HVAC (heating, ventilation, and air conditioning), and industrial systems. Whether in irrigation systems, water pumping stations, or wastewater treatment facilities, ball type foot valves are effective in managing fluid dynamics.

4. Durability and Reliability Constructed from sturdy materials, ball type foot valves are built to withstand harsh conditions and prolonged use. Their durability makes them a reliable choice for fluid control in demanding environments.

Applications of Ball Type Foot Valves

The applications of ball type foot valves are numerous and span various industries. In agricultural settings, they are commonly used in irrigation systems to ensure a steady supply of water while preventing runoff. In industrial processes, these valves are essential in maintaining the operational integrity of pumps by keeping them primed and preventing air from entering the system.

Moreover, in municipal water supply systems, ball type foot valves are critical in managing water flow and preventing contamination. They are also found in offshore and onshore oil and gas operations, where fluid control is paramount for safety and efficiency.

Conclusion

The ball type foot valve is an indispensable component in various fluid control systems, offering functionality, reliability, and ease of use. Understanding its design, advantages, and applications can help engineers, technicians, and operators make informed decisions when selecting valves for their systems. As industries continue to evolve and demand more efficient fluid management solutions, the role of ball type foot valves will undoubtedly remain significant in ensuring effective fluid dynamics across diverse applications. Whether in agricultural irrigation, industrial processes, or municipal water systems, these valves are pivotal in enhancing the safety and efficiency of fluid transport systems.

Share

-

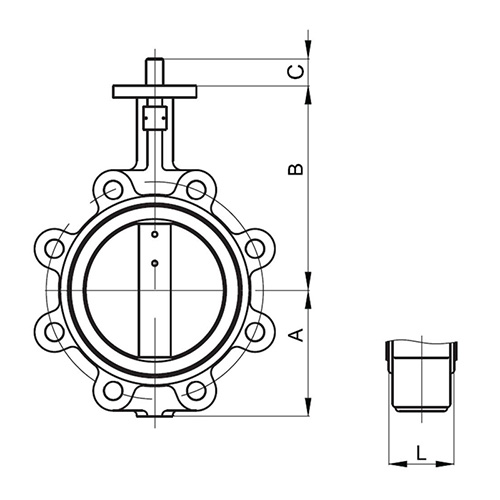

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025