Lis . 11, 2024 12:16 Back to list

api wafer type butterfly valve

Understanding API Wafer Type Butterfly Valves A Comprehensive Overview

In the realm of fluid control systems, butterfly valves are integral components that regulate flow and pressure in various applications. Among the different designs, the API (American Petroleum Institute) wafer type butterfly valve stands out due to its compact construction, efficiency, and versatility in a wide range of environments.

What is an API Wafer Type Butterfly Valve?

An API wafer type butterfly valve is characterized by its disc-shaped closure element, which rotates around a central axis. This valve is designed to fit between two flanges, resulting in a lightweight and space-efficient configuration. Its design simplifies installation, as it does not require additional support structures or external fittings. The wafer style allows for easy integration into existing pipelines, making it an attractive choice for many industrial applications.

Construction and Materials

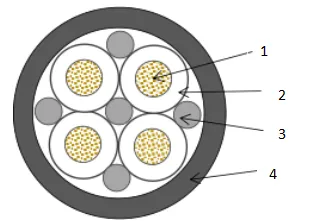

The construction of an API wafer type butterfly valve typically involves high-quality materials that ensure durability and resistance to wear. Common materials include stainless steel, ductile iron, and carbon steel, which provide excellent strength and corrosion resistance. The choice of material is crucial, particularly in industries such as oil and gas, where valves are exposed to extreme temperatures and aggressive fluids.

The sealing mechanism in these valves often incorporates rubber or polymer materials, such as EPDM, NBR, or PTFE, which enhance the valve's ability to prevent leakage. These seals are carefully designed to maintain their integrity under varying pressure and temperature conditions, ensuring reliable operation over time.

Operating Principle

The operation of an API wafer type butterfly valve is straightforward. When the valve is closed, the disc is positioned perpendicular to the flow direction, effectively blocking the passage of fluids. When the valve is opened, the disc rotates to a parallel position, allowing fluid to flow freely. This simple yet effective mechanism provides excellent control over the flow rate and pressure within the system.

Butterfly valves are known for their rapid cycling capabilities, making them suitable for applications that require quick shutdown or throttling functions. Their design allows for a minimal pressure loss across the valve, contributing to energy efficiency in system operations.

Applications

api wafer type butterfly valve

API wafer type butterfly valves are widely used across various industries, including

1. Oil and Gas These valves are essential in upstream, midstream, and downstream sectors to control the flow of crude oil, natural gas, and refined products.

2. Water Treatment In municipal and industrial water systems, these valves regulate water flow and are key components in filtration and treatment processes.

3. Chemical Processing The ability to handle aggressive chemicals makes wafer type butterfly valves a preferred choice in chemical plants, where precise flow control is crucial.

4. Power Generation In power plants, these valves are used in cooling water systems and various other applications where efficient flow control is vital.

Advantages of API Wafer Type Butterfly Valves

One of the primary advantages of API wafer type butterfly valves is their compact design, which requires less space compared to other valve types. This can result in significant savings in both installation and operational costs. Additionally, their lightweight nature facilitates easier handling and installation.

Another advantage is their low maintenance requirements. With fewer moving parts compared to gate or globe valves, wafer type butterfly valves typically require less frequent inspections and repairs. Their efficient sealing design also minimizes the risk of leakage, which is a critical aspect in maintaining operational efficiency and safety in various applications.

Conclusion

API wafer type butterfly valves play a critical role in managing fluid flow in numerous industries, thanks to their efficient design, durability, and versatility. Understanding their construction, operating principles, and applications can help engineers and procurement professionals make informed decisions. As industries continue to evolve, the importance of reliable valves like the API wafer type butterfly valve remains paramount in achieving operational excellence and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025