Srp . 19, 2025 09:51 Zpět na seznam

Advanced Technology in Wire and Cable Factory

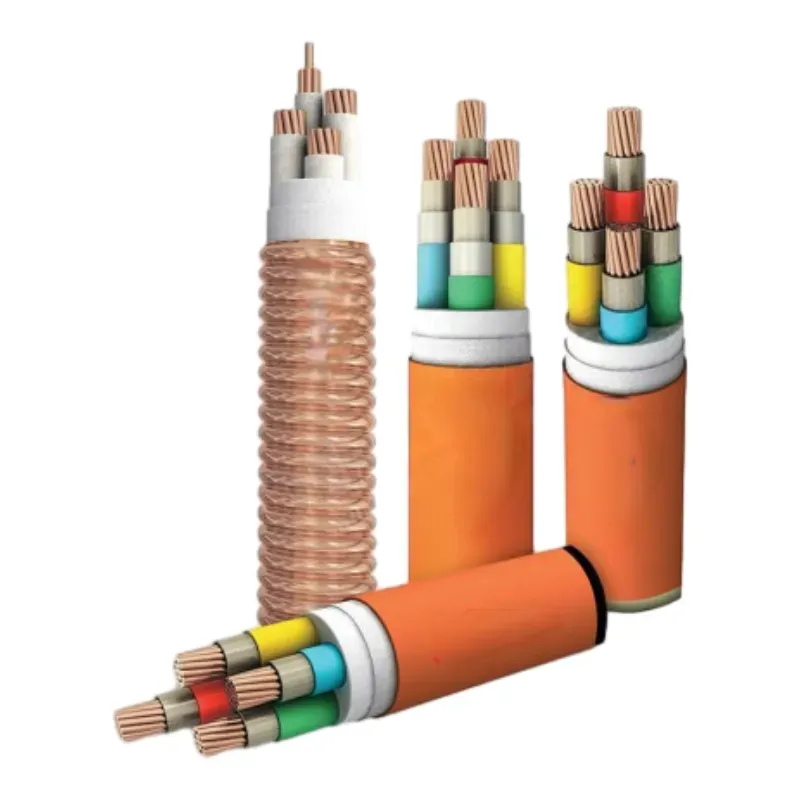

In the highly competitive landscape of the wire cable industry, the adoption of advanced technology in wire and cable factory operations has become a key determinant of success. It not only enhances the quality and reliability of wire cable products but also significantly boosts production efficiency. Hebei Honest Industrial Group Co., Ltd., a prominent name among wire cable manufacturers, has been at the forefront of integrating cutting - edge technologies into its manufacturing processes. This article explores the various advanced technologies employed in wire and cable factory settings, with a focus on how Hebei Honest Industrial Group Co., Ltd. leverages these technologies to stay ahead in the market.

Precision Manufacturing Technologies in Wire and Cable Factory

- High - Precision Extrusion Equipment: Hebei Honest Industrial Group Co., Ltd. utilizes state - of - the - art high - precision extrusion machines in its wire and cable factory. These machines are designed to ensure consistent and accurate coating of insulation materials on wire cable. The advanced control systems of the extrusion equipment can precisely regulate the temperature, pressure, and speed during the extrusion process. This precision results in wire cableproducts with uniform insulation thickness, which is crucial for electrical performance and safety. Whether it's for power transmission wire cable or data communication cables, the high - precision extrusion technology guarantees top - notch quality.

- The company employs CAD/CAM technology to optimize the design and manufacturing of wire cable. Engineers use CAD software to create detailed 3D models of cables, allowing for the simulation of different scenarios and the identification of potential design flaws before production. CAM systems then translate these designs into precise manufacturing instructions for the production equipment. This integration of CAD/CAM in the wire and cable factory not only speeds up the product development process but also enables the production of customized wire cable solutions to meet the diverse needs of customers.

Automation and Robotics in Wire Cable Production

- Automated Production Lines: Hebei Honest Industrial Group Co., Ltd. has established fully automated production lines in its wire and cable factory. These lines can handle multiple processes such as wire drawing, stranding, and cabling with minimal human intervention. Automated sensors and control systems monitor the production process in real - time, adjusting parameters as needed to maintain product quality. For example, during the stranding process of wire cable, the automated system ensures that the wires are twisted together with the correct pitch and tension. This automation not only increases production efficiency but also reduces the occurrence of human - error - related quality issues.

- Robotic Inspection and Testing: To ensure the quality of wire cableproducts, the company deploys robotic inspection systems in its factory. These robots are equipped with high - resolution cameras and advanced sensors to detect even the slightest defects in the cables, such as surface irregularities or insulation damage. Robots can also perform various tests, like electrical conductivity and tensile strength tests, with high precision and consistency. By relying on robotic inspection and testing, Hebei Honest Industrial Group Co., Ltd. can maintain strict quality control standards and quickly identify and address any potential problems in the wire cable production process.

Digitalization and Smart Manufacturing in Wire Cable Factory

- Internet of Things (IoT) Integration: The wire and cable factoryof Hebei Honest Industrial Group Co., Ltd. integrates IoT technology to create a smart manufacturing environment. IoT sensors are installed on production equipment, enabling real - time monitoring of machine performance, energy consumption, and production status. This data is collected and analyzed in the cloud, providing valuable insights for process optimization. For instance, by analyzing the data from IoT sensors, the company can predict when equipment maintenance is required, reducing downtime and increasing the overall productivity of the wire cable production line.

- Big Data Analytics: The company uses big data analytics to manage and improve its wire cableproduction processes. By analyzing large volumes of data from various sources, including production records, quality control reports, and customer feedback, Hebei Honest Industrial Group Co., Ltd. can identify trends and patterns. These insights are then used to make informed decisions regarding production scheduling, product design improvements, and supply chain management. Big data analytics thus plays a crucial role in enhancing the competitiveness of the company as a wire cable manufacturer in the global market.

Advanced Technology in Wire and Cable Factory FAQS

How does Hebei Honest Industrial Group Co., Ltd. benefit from advanced technology in its wire and cable factory?

Hebei Honest Industrial Group Co., Ltd. benefits from advanced technology in multiple ways. Precision manufacturing technologies ensure high - quality wire cable products, reducing the rate of defective items. Automation and robotics increase production efficiency, lower labor costs, and improve the consistency of production. Digitalization and smart manufacturing, through IoT integration and big data analytics, enable better process optimization, predictive maintenance, and more informed decision - making. All these aspects combined enhance the company's competitiveness as a leading wire cable manufacturer.

What are the main challenges in implementing advanced technology in a wire and cable factory?

Implementing advanced technology in a wire and cable factory can face several challenges. High initial investment costs for purchasing new equipment and software are a major hurdle. There is also a need for a skilled workforce to operate and maintain the advanced technology. Additionally, integrating new technologies with existing production systems can be complex and may require significant process re - engineering. Ensuring data security and privacy in digitalized manufacturing environments is another important challenge that wire cable manufacturers need to address.

Can advanced technology in a wire and cable factory improve product customization?

Yes, advanced technology can greatly improve product customization in a wire and cable factory. CAD/CAM technology allows for quick and easy design modifications based on customer requirements. Automated production lines can be reprogrammed to produce customized wire cable products with different specifications. Digitalization also enables better communication between the factory and customers, facilitating the understanding of specific customization needs and ensuring that the final products meet those requirements precisely.

How does advanced technology affect the safety of wire cable production?

Advanced technology enhances the safety of wire cable production in various ways. Automated production lines reduce the need for workers to perform dangerous tasks manually, minimizing the risk of workplace accidents. Robotic inspection systems can detect potential safety - related defects in wire cable products, preventing unsafe products from reaching the market. IoT - enabled equipment monitoring can also identify safety hazards in the production environment, such as abnormal machine vibrations or overheating, allowing for timely corrective actions.

What role does advanced technology play in the environmental sustainability of wire and cable factories?

Advanced technology in wire and cable factory operations contributes to environmental sustainability. Energy - efficient manufacturing equipment reduces energy consumption, lowering the factory's carbon footprint. Precision manufacturing technologies minimize material waste by ensuring accurate production. Big data analytics can optimize production processes, further reducing resource usage. Additionally, digitalization enables better management of waste disposal and recycling, helping wire cable manufacturers like Hebei Honest Industrial Group Co., Ltd. to adopt more environmentally friendly production practices.

Podíl

-

Applications of Ball Check Valve in Water Treatment PlantsZprávyAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingZprávyAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveZprávyAug.19,2025

-

Threaded Ball Valve Pressure RatingsZprávyAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisZprávyAug.19,2025