Oct . 14, 2024 17:19 Back to list

wafer style check valve

Understanding Wafer Style Check Valves

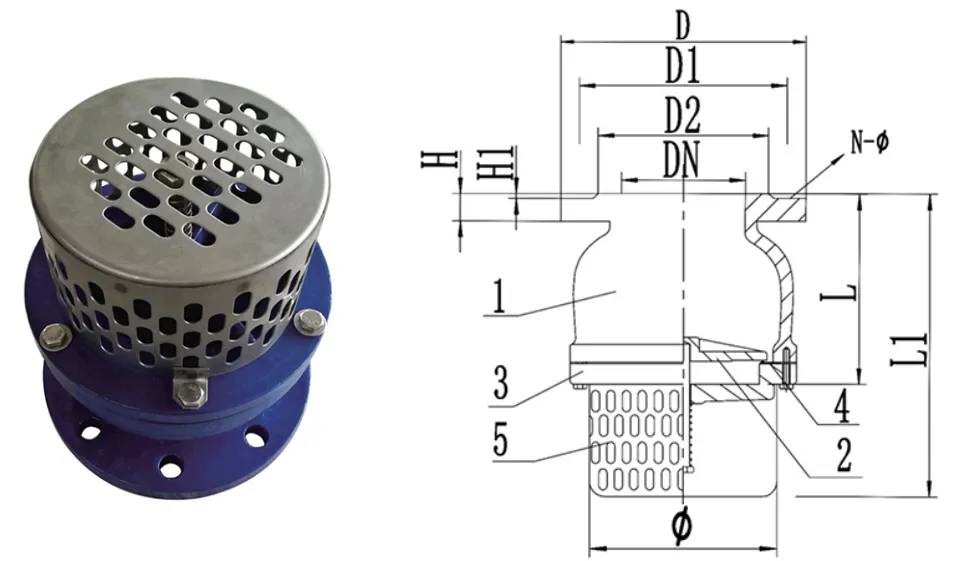

Wafer style check valves are essential components in various piping systems, designed primarily to prevent backflow and ensure the unidirectional flow of fluids. These valves are particularly popular in applications involving water, oil, and natural gas, making them an integral part of many industrial processes.

One defining feature of wafer check valves is their compact design. Unlike traditional check valves, which can be bulky and require considerable space, wafer check valves are slim and flat. This design allows them to fit snugly between flanges in a piping system, making them an ideal choice for tight installations. Their lightweight nature also contributes to ease of handling and installation, reducing the overall labor costs associated with maintenance and replacement.

In terms of functionality, wafer style check valves operate automatically based on pressure differences in the system. When fluid flows in the correct direction, the valve opens smoothly, allowing unrestricted flow. In the event of a reverse flow, the valve closes promptly due to the pressure drop, effectively preventing any backflow that could potentially harm the system or result in contamination. This passive operation means that wafer check valves do not require external energy sources, adding to their efficiency and reliability.

wafer style check valve

Material selection is another critical aspect when it comes to wafer check valves. They are typically constructed from a variety of materials, including stainless steel, ductile iron, and plastic, depending on the specific needs of the application. For instance, stainless steel valves are commonly used in corrosive environments due to their resistance to rust and degradation. It is crucial to choose the appropriate material to ensure durability and longevity, as this can significantly impact the valve's performance over time.

Installation and maintenance of wafer style check valves are generally straightforward. They can be installed in both horizontal and vertical piping configurations, which adds to their versatility. Regular inspections are recommended to ensure proper functioning, but thanks to their robust design, there is often minimal maintenance required.

In summary, wafer style check valves are a streamlined and efficient solution for preventing backflow in various fluid systems. Their compact design, automatic operation, and versatile materials make them a popular choice across many industries. Understanding their features and applications can aid in selecting the right valve for specific operational needs, ultimately ensuring system efficiency and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025