Dec . 01, 2024 04:14 Back to list

Types and Features of Di Wafer Butterfly Valves Explained in Detail

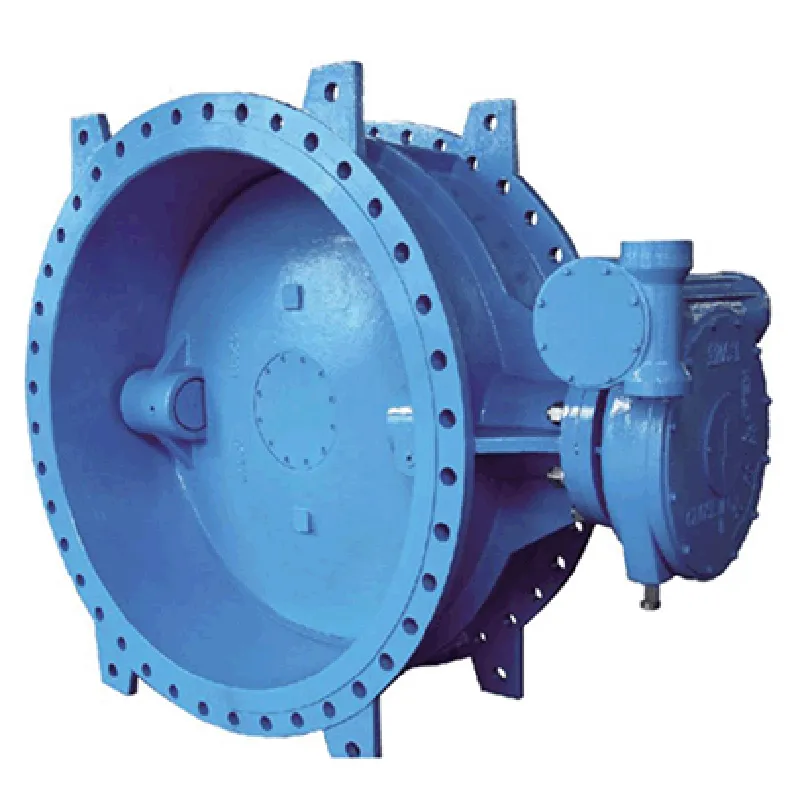

Understanding Di Wafer Type Butterfly Valves

In the world of fluid control systems, valves play a crucial role in regulating flow, pressure, and direction of liquids and gases. Among various types of valves, the double-insertion wafer type butterfly valve, commonly referred to as a di wafer type butterfly valve, stands out due to its compact design, ease of operation, and versatile application across different industries. This article delves into the features, advantages, applications, and maintenance aspects of di wafer type butterfly valves.

What is a Di Wafer Type Butterfly Valve?

Di wafer type butterfly valves are characterized by their unique design, which consists of a circular disc or butterfly that rotates around a central shaft. When the valve is in the open position, the disc is parallel to the flow direction, allowing fluid to pass through with minimal resistance. Conversely, when the valve is closed, the disc turns perpendicular to the flow, effectively blocking it. These valves are designed to fit between flanges in piping systems, which is what defines their wafer classification.

Key Features and Benefits

1. Compact and Lightweight Design One of the most significant advantages of di wafer type butterfly valves is their lightweight construction. This feature not only makes them easier to handle and install but also reduces the overall weight of the piping system.

2. Low Operating Torque The design of the butterfly valve allows for low torque requirements when opening and closing the valve. This characteristic simplifies the actuator sizing process and reduces energy consumption in automated systems.

3. Versatile Applications Di wafer type butterfly valves are suitable for a wide range of applications, including water treatment, mining, food and beverage processing, HVAC systems, and chemical manufacturing. They can handle various media, including slurries and corrosive liquids, especially when made from compatible materials such as stainless steel or PVC.

4. Space-Saving Solution Because these valves are installed between flanges rather than requiring additional space for a complete valve assembly, they are an excellent choice for systems with limited available space.

5. Cost-Effectiveness Di wafer type butterfly valves are usually more affordable compared to other valve types, making them an economically sound choice for many projects.

Applications

di wafer type butterfly valve

Di wafer type butterfly valves find their utility in a multitude of industrial scenarios

- Water Supply and Distribution Their ability to regulate flow and pressure makes them ideal for municipal water supply and wastewater management systems. - Heating, Ventilation, and Air Conditioning (HVAC) These valves are widely employed in HVAC systems for temperature control and airflow regulation. - Food and Beverage Industry The hygienic design and easy cleaning capabilities make them suitable for food processing applications. - Chemical and Petrochemical Industries Their robustness allows them to handle aggressive chemicals safely.

Maintenance and Care

To ensure the longevity and reliable operation of di wafer type butterfly valves, regular maintenance is essential. Here are some best practices

1. Routine Inspections Conduct periodic inspections for wear and tear, especially on the sealing surfaces and actuator components. Look for signs of leaks or corrosion.

2. Lubrication Proper lubrication of the valve shaft and moving parts reduces friction and wear, ensuring smooth operation.

3. Check for Alignment Misalignment can lead to increased wear or failure of the valve. Ensure that the valve is installed correctly and that the flanges are aligned.

4. Cleaning Regular cleaning is crucial, especially in food and beverage applications. Follow the manufacturer's recommendations for cleaning agents and methods.

5. Testing Routine functional tests will help detect any issues before they become critical, ensuring that the valve operates correctly in the system.

Conclusion

The di wafer type butterfly valve is a dynamic component in various industrial applications, offering an efficient and effective solution for flow management. With their compact design, low torque requirements, and versatility, these valves continue to gain popularity in diverse sectors. Proper maintenance and care are essential to maximize their performance and lifespan, ultimately leading to more efficient and reliable fluid control systems. Whether in your HVAC system or a large-scale chemical processing plant, understanding these valves is key to optimizing operations and achieving desired outcomes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025