Nov . 23, 2024 07:54 Back to list

2 inch rubber expansion joint

The Importance of 2% 20 Inch Rubber Expansion Joints in Modern Engineering

In the realm of modern engineering, the integrity and reliability of structures and systems are of paramount importance. One critical component that often goes unnoticed yet plays a vital role in various applications is the expansion joint. Specifically, the 20-inch rubber expansion joint, designed for accommodating up to 2% movement, has emerged as a key element in ensuring the durability and functionality of piping systems.

What is a Rubber Expansion Joint?

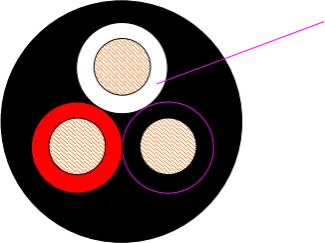

Rubber expansion joints are flexible connectors designed to absorb movement, vibration, and noise in piping systems. They are typically made from high-quality elastomeric materials that can withstand extreme temperatures and pressures. The design includes a flexible rubber section, which allows for axial, lateral, and angular movements, making them ideal for installations where thermal expansion and contraction occur.

Key Functions and Benefits

1. Thermal Expansion Accommodation As temperatures fluctuate, the materials within a piping system can expand or contract. A 20-inch rubber expansion joint can accommodate movements of up to 2%, effectively absorbing the stresses created by these changes. This capability is essential in preventing damage to pipes and associated fittings.

2. Vibration Isolation In many industrial applications, machinery generates vibrations that can lead to wear and tear on piping systems. Rubber expansion joints act as a buffer, isolating these vibrations and minimizing the potential for damage.

3. Noise Reduction The flexibility of rubber expansion joints also contributes to noise dampening. As fluids flow through pipelines, turbulent flow can create significant noise. By incorporating expansion joints, engineers can reduce the transmission of this noise, enhancing the overall function of the system.

2 inch rubber expansion joint

4. Corrosion Resistance Rubber materials are often resistant to various chemicals, making these joints an ideal choice for systems that handle corrosive substances. They help prevent leaks and corrosion-related issues that can compromise system integrity.

5. Ease of Installation Rubber expansion joints are generally lightweight and easy to install compared to metal counterparts. Their flexibility allows them to fit a range of configurations, simplifying the installation process and reducing labor costs.

Applications in Various Industries

The versatility of 20-inch rubber expansion joints allows for their use across multiple sectors

- Water and Wastewater Treatment In treatment plants, these expansion joints manage the thermal movements of pipes carrying water or sewage, prolonging the life of infrastructure. - Chemical Processing The chemical industry benefits from rubber joints due to their resistance to corrosive substances, essential for maintaining safety and functionality in processing plants. - HVAC Systems In heating, ventilation, and air conditioning systems, rubber expansion joints help manage the movements induced by temperature changes while minimizing noise and vibration for more comfortable environments. - Power Generation In power plants, these joints are critical for maintaining system integrity in high-temperature and high-pressure environments, ensuring efficient operation.

Conclusion

In summary, the 20-inch rubber expansion joint, capable of handling 2% movement, is an indispensable component in various engineering applications. Its ability to absorb thermal expansion, isolate vibrations, reduce noise, and resist corrosion makes it a reliable choice for industries ranging from water treatment to power generation. As engineering challenges continue to evolve, the role of such flexible connectors will undoubtedly remain crucial in ensuring the durability and efficiency of modern infrastructure. Emphasizing the importance of selecting the right materials and components, particularly rubber expansion joints, is a vital step toward achieving sustainable engineering solutions in an ever-demanding industrial landscape.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025