Dis . 04, 2024 14:19 Back to list

Non-Rising Stem Gate Valve Applications and Benefits in Various Industries

Non-Rising Stem Gate Valve An In-Depth Overview

In various industrial applications, the efficient control of fluid flow is critical, and one essential piece of equipment that facilitates this is the gate valve. Among the many types of gate valves available, the non-rising stem gate valve stands out for its unique design and functional advantages. This article will explore the features, benefits, applications, and maintenance of non-rising stem gate valves.

Understanding Non-Rising Stem Gate Valves

A non-rising stem gate valve operates using a threaded shaft that moves the gate up and down to open or close the valve. Unlike rising stem gate valves, where the stem rises out of the valve as it opens, non-rising stem valves maintain a fixed stem length that does not extend out of the valve body. This design is particularly advantageous in situations where vertical space is limited or where the valve is installed in a confined area.

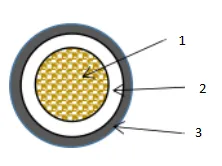

The key components of a non-rising stem gate valve include the body, gate, stem, and the packing gland, which ensures a tight seal around the stem. Most non-rising stem gate valves are made from robust materials such as cast iron, bronze, or stainless steel, enabling them to withstand high pressures and corrosive environments.

Advantages of Non-Rising Stem Gate Valves

The non-rising design presents several benefits

1. Space Efficiency Non-rising stem gate valves require less vertical space, making them ideal for installations where headroom is limited, such as underground pipes or tight mechanical rooms.

2. Reduced Wear and Tear Since the stem does not rise, there is less exposure to external elements, reducing wear and extending the lifespan of the valve.

3. Cost-Effectiveness These valves often have a simpler construction, which can result in lower manufacturing and maintenance costs compared to rising stem variants.

4. Ease of Operation Non-rising stem gate valves can be manually operated or actuated easily, providing reliable functionality.

5. Versatility They can be used in various industries, including water treatment, oil and gas, and chemical processing, where controlling fluid flow is paramount.

non rising stem gate valve

Applications

Non-rising stem gate valves are utilized in multiple sectors due to their design advantages

. Common applications include- Water Supply and Wastewater Management These valves are crucial for controlling water flow in pipelines, ensuring the efficient management of water resources. - Oil and Gas Industry Non-rising stem gate valves help regulate the flow of crude oil, natural gas, and other hydrocarbons, adapting well to the demanding conditions of this sector.

- Chemical Processing Their excellent sealing capability makes them suitable for handling corrosive substances in chemical plants.

- Fire Protection Systems These valves can be integral to fire suppression systems, where reliable shut-off capabilities are essential.

Maintenance Considerations

To ensure optimal performance, regular maintenance of non-rising stem gate valves is crucial. Users should follow these maintenance tips

- Routine Inspection Regular checks for leaks, rust, or signs of wear can preempt larger issues. - Lubrication Keeping the stem lubricated can prevent corrosion and ensure smooth operation.

- Testing Functionality Periodic testing of the valve under operating conditions can help verify its reliability and response time.

- Scheduled Replacement Depending on the use and material, a planned replacement schedule can be beneficial to avoid unexpected failures.

Conclusion

Non-rising stem gate valves offer a space-efficient and durable solution for controlling fluid flow across various industries. Their unique design and operational advantages make them a preferred choice in many applications, ensuring reliable service and enhanced safety. By understanding their features and maintaining them properly, users can maximize the performance and longevity of these valuable components in their systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025