Dis . 07, 2024 09:35 Back to list

lined butterfly valve

Understanding Lined Butterfly Valves Features and Applications

Butterfly valves are crucial components widely used in various industries for regulation and control of fluid flow. Among the various types of butterfly valves, lined butterfly valves stand out due to their unique construction and operational advantages. This article will explore the features, benefits, and applications of lined butterfly valves, highlighting their importance in modern fluid handling systems.

What is a Lined Butterfly Valve?

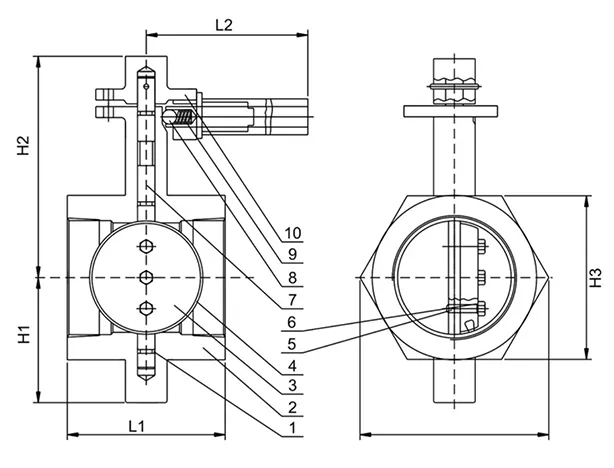

A lined butterfly valve is a type of valve consisting of a circular disk, known as a butterfly, which rotates around a central shaft. The lining of the valve is made from materials such as PTFE (polytetrafluoroethylene) or other polymer compounds that provide excellent chemical resistance and durability. The primary function of the butterfly valve is to start, stop, and regulate the flow of liquids or gases in a pipeline.

Features of Lined Butterfly Valves

1. Chemical Resistance One of the standout features of lined butterfly valves is their ability to handle aggressive chemicals. The lining material protects the metal body of the valve from corrosive substances, making it ideal for applications in chemical processing, pharmaceuticals, and wastewater management.

2. Lightweight Design Lined butterfly valves are generally lighter than other valve types, such as ball or gate valves. This reduced weight makes them easier to install and manage, especially in large-diameter piping where heavy valves could pose logistical challenges.

3. Space Efficiency Their compact design enables lined butterfly valves to occupy less space in piping systems, which is particularly beneficial in environments with limited installation areas.

4. Quick Operation Lined butterfly valves typically require only a quarter turn to fully open or close, enabling rapid operation and efficient process control. This feature is crucial in applications requiring swift adjustments in flow management.

5. Versatile Applications These valves can be used in a wide range of applications, from simple on-off services to throttling and flow control. Their versatility makes them suitable for various industries, including water supply, oil and gas, food and beverage, and power generation.

Benefits of Using Lined Butterfly Valves

1. Longevity and Maintenance The resistant lining material extends the lifespan of the valve, reducing maintenance needs and costs. Users can expect longer service intervals compared to unlined valves, which may corrode over time.

lined butterfly valve

2. Reduced Possibility of Leakage The design and construction of lined butterfly valves minimize the risk of leakage, contributing to safer operational environments. This is particularly important in industries dealing with hazardous or toxic materials.

3. Significant Cost Savings Although the initial investment in lined butterfly valves may be higher due to their specialized materials and construction, the long-term savings from reduced maintenance, downtime, and replacement make them a cost-effective choice.

4. Environmental Protection By preventing leaks and corrosion, lined butterfly valves play a crucial role in minimizing environmental contamination, supporting sustainable industry practices.

Applications of Lined Butterfly Valves

1. Chemical Processing In any facility handling corrosive chemicals, lined butterfly valves provide the necessary durability and reliability to manage processes safely.

2. Food and Beverage Sanitary lined butterfly valves are essential in the food industry, where they help ensure compliance with health and safety standards while maintaining product quality.

3. Water Treatment In municipal and industrial water treatment facilities, these valves regulate flow rates and control processes critical for purification and distribution.

4. Power Generation Lined butterfly valves are employed in power plants to manage fluids and help maintain efficiency in energy production.

5. Pharmaceuticals The pharmaceutical industry demands equipment that maintains the integrity of the products being processed. Lined butterfly valves meet this need effectively through their sanitary design and protective coatings.

Conclusion

Lined butterfly valves are indispensable in various industrial applications due to their chemical resistance, lightweight design, and excellent flow control capabilities. With their multiple benefits, including reduced maintenance costs and enhanced safety, they serve as an ideal solution for many fluid handling needs. As industries continue to seek efficient, reliable, and environmentally responsible options, the demand for lined butterfly valves is likely to increase, solidifying their role in modern engineering and process management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025