Nov . 16, 2024 01:32 Back to list

grooved butterfly valve

The Grooved Butterfly Valve A Comprehensive Overview

In the realm of fluid control systems, butterfly valves are essential components known for their effective flow regulation capabilities. Among various types, the grooved butterfly valve stands out for its unique design and application versatility. This article delves into the features, benefits, applications, and maintenance of grooved butterfly valves, offering insights into why they are a preferred choice in many industries.

What is a Grooved Butterfly Valve?

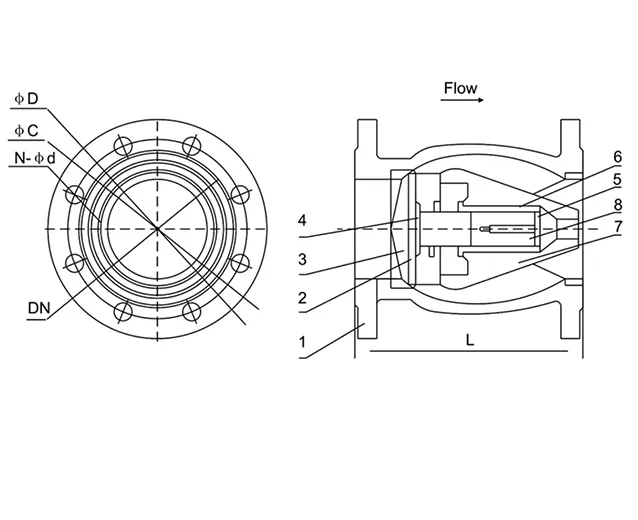

A grooved butterfly valve is characterized by its circular disc, which rotates around an axis in the center of the valve body. The ‘grooved’ aspect refers to the connection method used for installation. Instead of traditional welding or flanged connections, grooved butterfly valves use a groove on the valve’s ends to facilitate secure connections with pipes. This design allows for easier installation and offers the potential for quick disassembly and maintenance.

Key Features

1. Compact Design The grooved butterfly valve is typically more compact than other valve types, making it ideal for installations where space is limited. This feature also reduces the overall weight of the piping system.

2. Flow Control The valve’s disc can be easily adjusted to regulate flow effectively. It provides a linear relationship between the valve position and flow rate, enabling precise control over the fluid movement.

3. Quick-Actuating Many grooved butterfly valves are equipped with quick-acting mechanisms, allowing for swift opening and closing. This is particularly beneficial in emergency situations where prompt action is required.

4. Durability Grooved butterfly valves are commonly made from robust materials, such as stainless steel, ductile iron, or PVC, offering resistance to corrosion, pressure, and temperature fluctuations. This durability extends the valve’s lifespan, reducing replacement costs over time.

Benefits

1. Ease of Installation The grooved connection makes installation significantly easier compared to traditional valves. This means reduced labor costs and time during the installation phase of piping systems.

2. Maintenance Convenience The design allows for easy disassembly, making maintenance and repairs straightforward. This feature is crucial in minimizing downtime in industrial applications.

3. Versatile Applications Grooved butterfly valves are suitable for a wide range of applications, including water supply systems, HVAC systems, chemical processing, and fire protection systems. Their adaptability is one of the reasons they are widely used across multiple industries.

grooved butterfly valve

Applications

Grooved butterfly valves are prevalent in various sectors due to their flexible design and reliable performance

. Some notable applications include- Water Treatment Plants In these facilities, grooved butterfly valves help regulate the flow of water through different treatment stages, ensuring that processes run smoothly.

- HVAC Systems These valves are utilized in heating, ventilation, and air conditioning systems for flow regulation and to ensure efficient temperature control.

- Chemical Processing Their robust construction makes them suitable for handling corrosive fluids in chemical manufacturing processes.

- Fire Protection Grooved butterfly valves are widely used in fire sprinkler systems, allowing for effective control of the water supply during emergencies.

Maintenance Tips

To ensure the longevity and optimal performance of grooved butterfly valves, regular maintenance is essential. Here are some tips

- Regular Inspections Periodically check for any signs of wear or damage. Look for leaks around the grooved connection and inspect the valve seat and disc for degradation.

- Lubrication Ensure that the valve's moving parts are adequately lubricated to prevent sticking and to ensure smooth operation.

- Cleaning Keep the valve free from debris and buildup that could interfere with its function.

Conclusion

The grooved butterfly valve offers a unique combination of efficiency, durability, and ease of use, making it an excellent choice for a variety of applications in fluid control systems. With proper maintenance and care, these valves can provide reliable service for years, proving their worth as a vital component in industrial and commercial settings. As industries continue to evolve, the role of innovative solutions like the grooved butterfly valve will undoubtedly grow, enhancing fluid management processes across the board.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025