Dis . 22, 2024 04:46 Back to list

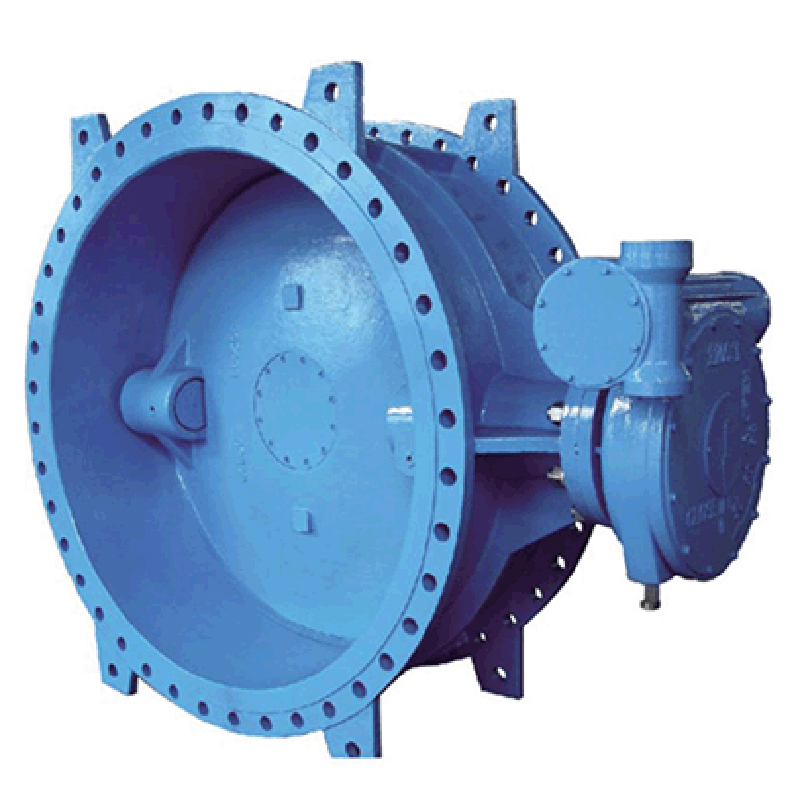

flanged ball valve

Flanged Ball Valves An Essential Component in Fluid Control

In the realm of fluid control systems, flanged ball valves play a crucial role in ensuring optimal performance and reliability. These valves are known for their robust design and efficient operation, making them indispensable in various industrial applications, including oil and gas, water treatment, chemical processing, and HVAC systems. Understanding the features, benefits, and applications of flanged ball valves can provide valuable insights into their importance in maintaining fluid systems.

What is a Flanged Ball Valve?

A flanged ball valve is a type of quarter-turn valve that utilizes a spherical disc, known as the ball, to control the flow of fluid through a pipe. The key characteristic that differentiates flanged ball valves from other types is the flange connections on their ends. These flanges facilitate easy installation and disconnection from piping systems, allowing for effective maintenance and replacement without significant system downtime.

The ball within the valve has a hole through the center, aligned with the pipe when the valve is open, allowing fluid to flow freely. When the valve is closed, the ball is rotated 90 degrees, effectively blocking the flow. This straightforward mechanism provides a quick and reliable method to control fluid movement.

Advantages of Flanged Ball Valves

1. Easy Installation The flanged design allows for straightforward alignment and attachment to piping systems. Flanged ball valves can be easily bolted to the pipes, offering a secure and leak-proof connection.

2. Durability and Reliability Made from robust materials such as stainless steel, carbon steel, or plastic, flanged ball valves are designed to withstand high pressures and temperatures. Their durable construction ensures a long service life, making them a cost-effective choice for industrial applications.

flanged ball valve

3. Minimal Flow Resistance The spherical design of the ball results in minimal flow resistance, allowing for efficient fluid transport. This low-pressure drop performance is essential in maintaining energy efficiency in systems.

4. Versatile Applications Flanged ball valves can be used in various applications, including on/off control, throttling, and flow regulation. Their versatility makes them suitable for handling different types of fluids, including gases, liquids, corrosive materials, and slurries.

5. Low Maintenance Requirements Due to their simple operating mechanism, flanged ball valves require minimal maintenance compared to other valve types. Regular inspections and occasional lubrication are typically sufficient to ensure continued functionality.

Applications of Flanged Ball Valves

Flanged ball valves are widely used across numerous industries. In the oil and gas sector, they are crucial for regulating the flow of crude oil and natural gas. In chemical manufacturing, these valves control the flow of various chemicals and ensure safety in potentially hazardous environments. Water treatment facilities utilize flanged ball valves to control water distribution and manage sewage systems. Additionally, they are integral to heating, ventilation, and air conditioning (HVAC) systems, where they help regulate temperature and airflow.

Conclusion

Flanged ball valves are an essential component in fluid control systems, offering a combination of durability, efficiency, and reliability. Their ease of installation, low maintenance requirements, and versatility make them a preferred choice in various industrial applications. As industries continue to evolve, the demand for efficient fluid control solutions will only increase, ensuring that flanged ball valves remain at the forefront of technology in fluid management. Investing in quality flanged ball valves not only enhances operational efficiency but also contributes to the safety and reliability of complex fluid systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025