Nov . 17, 2024 09:10 Back to list

ci dismantling joint

Understanding CI Dismantling Joint Necessity and Implementation

In the realm of engineering and construction, the need for optimal functionality and safety can never be overstated. One of the critical components in various industrial applications is the CI (Cast Iron) dismantling joint. Designed to facilitate the maintenance and replacement of pipelines without the need for extensive labor or resource investment, dismantling joints are an essential innovation in modern piping systems.

What is a CI Dismantling Joint?

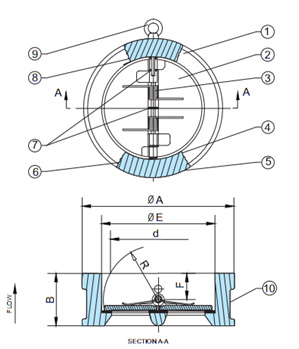

A CI dismantling joint is essentially a mechanical device used in piping systems that allows for the easy disassembly and reassembly of sections of pipe. By enabling access to pipes without requiring a complete shut down or complex disassembly of adjoining components, these joints greatly enhance the efficiency of maintenance processes. The use of cast iron as a base material offers the joint significant strength and durability, making it suitable for heavy-duty applications.

Importance of Dismantling Joints in Pipelines

One of the most significant advantages of employing CI dismantling joints lies in the convenience they offer during the maintenance of water and sewage systems. In urban environments, where space is often limited, and access to underground pipelines can be challenging, dismantling joints allow workers to make adjustments quickly without disturbing the entire infrastructure.

Moreover, these joints play a crucial role in preventing potential leaks and other failures. Regular inspections become far more manageable, as the ease of access encourages routine maintenance, thus prolonging the lifespan of the system overall. By allowing for swift and effective maintenance protocols, CI dismantling joints reduce the economic implications of infrastructure downtime.

Design and Functionality

ci dismantling joint

The design of a CI dismantling joint often features an elongated body that allows for the adjustment of alignment and the easy removal of pipe segments. This flexibility is incorporated into the design to accommodate any variations in the piping system, which can arise due to ground settlement or thermal expansion. With bolted connections, dismantling joints can be installed and removed with minimal tools, ensuring that maintenance teams can respond promptly to any required repairs or modifications.

The joint's construction is engineered to handle not just the physical stress imposed by fluid transportation but also the inevitable wear and tear that results from environmental conditions. The properties of cast iron make it resistant to corrosion and provide superior performance over time in demanding applications.

Challenges and Considerations

Despite their numerous advantages, there are important considerations when integrating CI dismantling joints into a piping system. Proper installation is crucial; misalignment during installation can lead to premature failure or system inefficiencies. Furthermore, the selection of the right joint size and type is paramount; it should match the specific requirements of the pipeline system, ensuring that it can withstand operational pressures and flow rates effectively.

Another factor to consider is the joint's exposure to various corrosive substances. While cast iron is generally robust, environments with certain chemicals might necessitate additional protective measures or even the consideration of alternative materials such as stainless steel or ductile iron.

Conclusion

In summary, CI dismantling joints represent a vital component in the maintenance and operation of pipeline systems. Their ease of use and reliability offer substantial benefits for both routine inspections and long-term structural integrity. As the demands of modern infrastructure continue to grow, the integration of innovative solutions such as dismantling joints in construction and engineering practices will ensure that efficiency and safety remain paramount in our industrial undertakings. The careful consideration of design, placement, and material selection will enhance functional longevity, paving the way for a safer and more efficient future in piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025