Ene . 09, 2025 11:43 Back to list

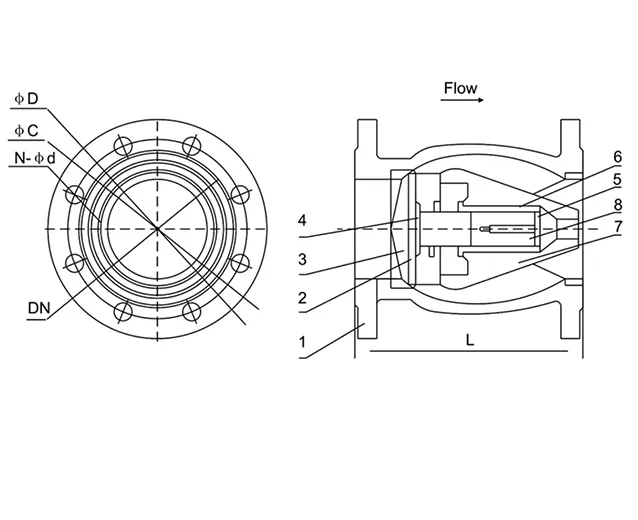

ball type check valve

The check valve, a seemingly simple device, plays a pivotal role in fluid control systems across various industries. As a critical component, it ensures unidirectional flow, preventing the backflow that can compromise system integrity. Whether in potable water systems, oil and gas pipelines, or chemical processing plants, the application of check valves underscores their indispensability.

Real-world applications provide further insight into the operational dynamics of check valves. In municipal water systems, for example, check valves are pivotal in maintaining water quality and system pressure. Their deployment prevents contamination from backflow and safeguards public health—a responsibility that underscores their critical role in civic infrastructure. Moreover, in HVAC systems, check valves help maintain desired flow directions, contributing to energy efficiency and system efficacy. Manufacturers continue to innovate, enhancing the versatility and reliability of check valves. Recent advancements have introduced smart check valves equipped with sensors and real-time monitoring capabilities. These innovations offer engineers unprecedented oversight, allowing for predictive maintenance and reducing the risk of unexpected failures. The integration of IoT technology into check valve systems exemplifies the merging of traditional engineering with modern innovation—a forward-thinking approach that only strengthens the authority and trustworthiness of these components. The uniqueness of each system requires customized solutions, and it is here that the true expertise in check valve application shines. A process engineer shares a narrative of working with a multidisciplinary team to address a unique challenge in a pharmaceutical plant. The team’s collaboration and comprehensive understanding of fluid dynamics led to the integration of a specific ball check valve that performed flawlessly, bolstering the plant’s production efficiency. The check valve may appear to be a modest component but is integral to the seamless operation of complex systems. Its ability to provide secure flow control, backed by material durability, innovative technology, and expert deployment, reinforces its authoritative standing in the world of fluid dynamics. For anyone invested in system reliability and efficiency, understanding the nuances of check valve selection and application is not only beneficial but essential. The continuous evolution in design and technology promises an even more secure future for these indispensable devices.

Real-world applications provide further insight into the operational dynamics of check valves. In municipal water systems, for example, check valves are pivotal in maintaining water quality and system pressure. Their deployment prevents contamination from backflow and safeguards public health—a responsibility that underscores their critical role in civic infrastructure. Moreover, in HVAC systems, check valves help maintain desired flow directions, contributing to energy efficiency and system efficacy. Manufacturers continue to innovate, enhancing the versatility and reliability of check valves. Recent advancements have introduced smart check valves equipped with sensors and real-time monitoring capabilities. These innovations offer engineers unprecedented oversight, allowing for predictive maintenance and reducing the risk of unexpected failures. The integration of IoT technology into check valve systems exemplifies the merging of traditional engineering with modern innovation—a forward-thinking approach that only strengthens the authority and trustworthiness of these components. The uniqueness of each system requires customized solutions, and it is here that the true expertise in check valve application shines. A process engineer shares a narrative of working with a multidisciplinary team to address a unique challenge in a pharmaceutical plant. The team’s collaboration and comprehensive understanding of fluid dynamics led to the integration of a specific ball check valve that performed flawlessly, bolstering the plant’s production efficiency. The check valve may appear to be a modest component but is integral to the seamless operation of complex systems. Its ability to provide secure flow control, backed by material durability, innovative technology, and expert deployment, reinforces its authoritative standing in the world of fluid dynamics. For anyone invested in system reliability and efficiency, understanding the nuances of check valve selection and application is not only beneficial but essential. The continuous evolution in design and technology promises an even more secure future for these indispensable devices.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025