nov . 15, 2024 13:04 Back to list

double ball check valve

The Double Ball Check Valve A Critical Component in Fluid Systems

In the realm of fluid control systems, the double ball check valve stands as an essential component, offering reliability and efficiency in preventing backflow. This innovative device is predominantly used in various applications, from industrial operations to residential plumbing, ensuring that fluids flow in one direction without allowing reverse flow that could cause system malfunctions.

What is a Double Ball Check Valve?

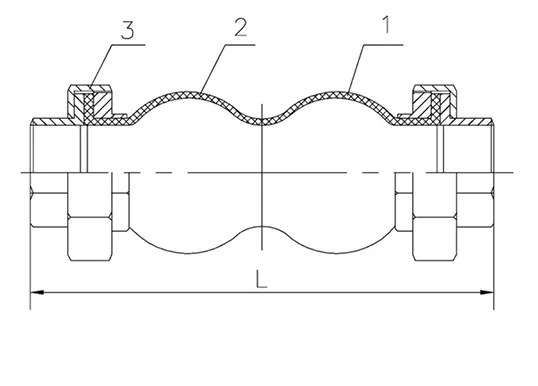

The double ball check valve is a type of one-way valve that utilizes two ball-shaped elements within its housing to control the flow of fluid. When fluid flows in the desired direction, the balls are pushed away from their seats, allowing passage. However, if there is an attempt at backflow, the pressure forces the balls to seat against the valve, effectively blocking any reverse flow. This mechanism makes the double ball check valve particularly efficient and reliable, as it eliminates the risk of backflow that can lead to contamination or system failure.

Applications and Benefits

Double ball check valves find their applications in various fields, including oil and gas, water treatment, and HVAC systems. In the oil and gas industry, they are critical for preventing the backflow of oil, which ensures the safety and integrity of pipelines. In water treatment facilities, these valves help maintain the purity of drinking water by preventing contaminants from entering the clean supply.

double ball check valve

One of the primary benefits of using a double ball check valve is its simplicity and low maintenance requirements. The design minimizes the complexity of installation and operation, making it easier for engineers and technicians to incorporate them into existing systems. Additionally, the robust construction of these valves ensures a long service life, reducing the frequency of replacements and repairs.

Design and Material Considerations

When selecting a double ball check valve, several design and material considerations come into play. The choice of materials, such as stainless steel, brass, or plastic, impacts the valve's durability and its ability to withstand varying pressures and temperatures. The size and flow rate of the valve are also critical factors, as they must align with the specific requirements of the system in which they are installed.

Moreover, manufacturers often design these valves to operate in challenging environments, providing options for high-pressure or corrosive applications. This adaptability makes the double ball check valve a versatile solution across multiple industries.

Conclusion

In conclusion, the double ball check valve is a vital component in fluid systems, enabling efficient and safe control of fluid flow. Its unique design prevents backflow effectively, safeguarding systems from potential failures and contamination. With various applications and benefits, it is clear that this simple yet ingenious mechanism plays a crucial role in maintaining the integrity of fluid management across diverse fields. As technology continues to advance, innovations in double ball check valves will likely enhance their performance and reliability, further solidifying their importance in engineering and industrial applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025