অক্টো. . 31, 2024 07:19 Back to list

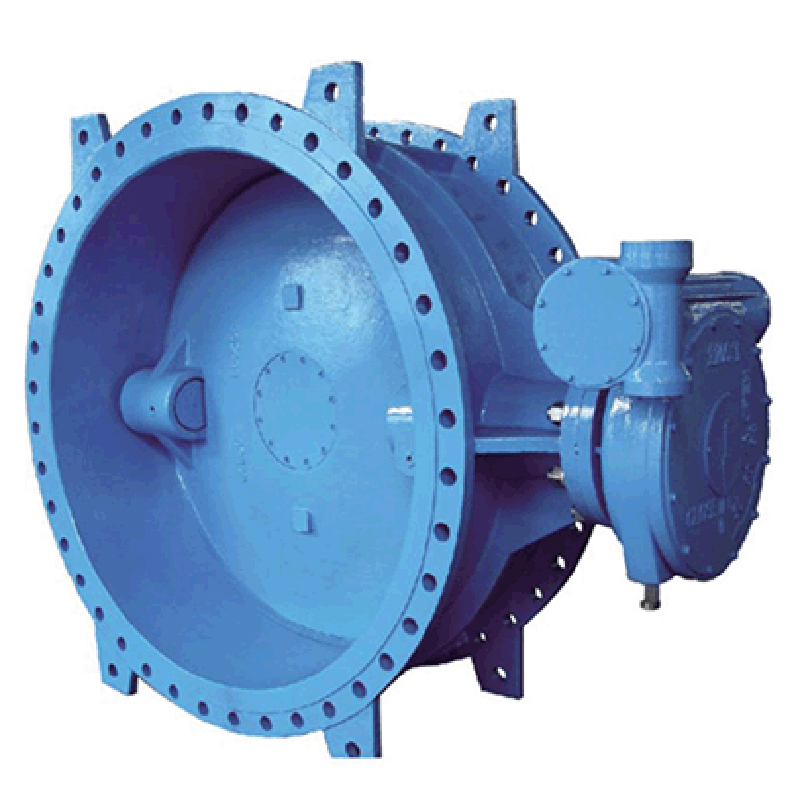

concentric lug type butterfly valve

The concentric lug type butterfly valve is an indispensable component in various industrial applications, known for its efficiency in controlling fluid flow. This valve design exhibits several features that make it ideal for a range of environments, including water supply systems, oil and gas, and chemical processing.

At the heart of a concentric lug type butterfly valve is its unique structure. The term “concentric” refers to the alignment of the valve disc and the body. Unlike eccentric designs, where the disc is offset from the seat, the concentric design has the disc positioned centrally, allowing it to rotate seamlessly within the flow path. This symmetry contributes to a more uniform flow when the valve is open, minimizing turbulence and pressure drops.

One of the primary advantages of a concentric lug type butterfly valve is its simplicity

. The design often includes fewer moving parts compared to other types of valves, which not only reduces the potential for mechanical failure but also makes it easier to operate and maintain. The valve typically consists of a circular disc hinged on a shaft, which can be turned to open or close the flow.Moreover, the lugs found on this butterfly valve are critical for mounting. They provide a secure attachment to the pipeline, allowing the valve to be easily installed and removed as necessary. This feature is especially beneficial in process industries where maintenance and repairs are frequently required. The lug design effectively transmits pipeline pressure to the valve body, making it suitable for high-pressure applications.

concentric lug type butterfly valve

The versatile material options available for concentric lug type butterfly valves contribute to their widespread use. Manufacturers often produce these valves using materials such as stainless steel, cast iron, or plastic, with each material catering to specific environmental conditions. For instance, stainless steel is favored in corrosive settings, while cast iron may be used for standard water applications.

Another key benefit of these valves is their tight sealing capabilities. When closed, the concentric design ensures that the valve seat tightly seals against the disc, preventing leaks. This characteristic is crucial in industries that handle hazardous fluids or require strict adherence to safety standards. The reliability of the valve’s sealing mechanism minimizes the risk of contamination and ensures operational safety.

In terms of adaptability, concentric lug type butterfly valves can be operated manually or automated with the use of actuators. Electric or pneumatic actuators provide precise control over the valve, allowing for remote operation in large facilities. This automation makes it easier to integrate these valves into broader control systems, enhancing process efficiency.

As industries continue to evolve, the demand for robust, efficient, and reliable fluid control solutions grows. The concentric lug type butterfly valve stands out due to its efficient design, minimal maintenance requirements, and adaptability across various applications. As technology advances, we can anticipate further innovations in valve design and performance, solidifying the concentric lug type butterfly valve's position in the world of industrial fluid control. In conclusion, its combination of functional design, reliability, and versatility makes it an essential choice for engineers and operators alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025