Ліст . 09, 2024 18:38 Back to list

Wire and Cable Manufacturing Facility with Advanced Technology and Quality Control

Exploring the World of Wire and Cable Manufacturing

In today's technologically driven world, wires and cables are essential components that power our daily lives. From electrical systems in homes to complex telecommunications networks, the manufacturing of wire and cable plays a critical role in various industries. This article delves into the intricacies of wire and cable factories, shedding light on their processes, importance, and advancements in technology.

The Manufacturing Process

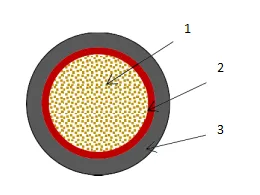

The manufacturing process of wire and cable begins with the selection of raw materials, predominantly copper and aluminum due to their excellent conductivity. These metals are drawn into wires through a series of mechanical and thermal processes, involving multiple stages such as wire drawing, annealing, and insulation. Wire drawing reduces the diameter of the metal rods, while annealing serves to relieve stress and enhance ductility.

After the wires are drawn, insulation is applied. This is a vital step that protects the wires from environmental factors and electrical interference. Varieties of insulative materials are available, including rubber, PVC, and cross-linked polyethylene, each chosen based on the cable's intended application. The manufacturing process may further include sheathing, which adds an extra layer of protection against physical damage.

Quality Control and Standards

Quality assurance is paramount in the wire and cable manufacturing industry. Factories adhere to strict standards set by organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). Rigorous testing methods are employed to ensure that products meet safety and performance requirements. These tests assess tensile strength, conductivity, insulation integrity, and resistance to environmental factors.

Furthermore, many manufacturers implement advanced Quality Management Systems (QMS) to monitor and improve their processes continuously. By adopting practices such as Six Sigma and Total Quality Management (TQM), these factories can minimize defects and enhance product consistency.

wire and cable factory

Importance of Innovation

The wire and cable industry is no stranger to innovation. As technology evolves, so too does the need for more efficient and sophisticated cabling solutions. The rise of renewable energy sources has led to the development of specialized cables for solar and wind energy applications. Additionally, advancements in telecommunications, such as the rollout of 5G networks, have prompted the creation of high-speed cables with enhanced data transmission capabilities.

Smart technology is also making its way into wire and cable design. Manufacturers are exploring the integration of sensors within cables to monitor conditions such as temperature, humidity, and strain. This capability can help in predictive maintenance and prevent catastrophic failures in critical infrastructure.

Environmental Considerations

As the world becomes increasingly conscious of environmental issues, wire and cable factories are making strides toward sustainable practices. Many manufacturers are now focusing on eco-friendly materials and recycling methods. Efforts are also being made to reduce waste and energy consumption during production.

The development of biodegradable insulation materials and the adoption of circular economy principles—where products are reused or recycled rather than discarded—are notable trends in the industry. By prioritizing sustainability, manufacturers not only comply with regulations but also respond to consumer demand for greener products.

Conclusion

Wire and cable factories are the backbone of modern infrastructure, facilitating the transmission of electricity and data across the globe. Through meticulous manufacturing processes, stringent quality control, innovative technologies, and a commitment to sustainability, these factories continue to evolve. As we move forward into an era of rapid technological advancement, the wire and cable industry will undoubtedly play a pivotal role in shaping the future of connectivity and energy efficiency.

Share