снеж . 06, 2024 03:08 Back to list

pipe dismantling joint

Understanding Pipe Dismantling Joints An Essential Component in Pipeline Systems

Pipeline systems are integral to industries such as water distribution, oil and gas transport, and wastewater management. One crucial component that ensures the efficiency and reliability of these systems is the dismantling joint. This article explores the purpose, types, benefits, installation, and maintenance of pipe dismantling joints.

What is a Pipe Dismantling Joint?

A pipe dismantling joint is a specialized fitting used in piping systems to facilitate the disassembly and maintenance of pipe sections without the need for complete removal of other components. These joints allow for easier access to valves, pumps, and other fittings in the pipeline, making repairs, replacements, and inspections more manageable.

Purpose and Benefits

The primary purpose of a dismantling joint is to provide flexibility in pipeline operations. Below are several key benefits associated with the use of dismantling joints

1. Ease of Maintenance In situations where components need to be accessed for repair or replacement, dismantling joints minimize the need for extensive excavation or complete disassembly of the entire pipeline.

2. Cost-Effectiveness By reducing labor hours and minimizing disruptions, dismantling joints can lead to significant cost savings in the long run for both installation and maintenance.

3. Versatility Dismantling joints can be used in various applications, including water supply, wastewater management, and industrial processes. Their design allows compatibility with multiple pipe materials and sizes.

4. Alignment Correction When installed, dismantling joints can help correct minor misalignments in the piping system, ensuring proper flow and reducing stress on connections.

5. Minimized Downtime Since maintenance can be performed more efficiently, the downtime of operations is significantly reduced, leading to consistent service delivery.

Types of Dismantling Joints

Dismantling joints come in various designs, each suited for specific applications. Some common types include

1. Flanged Dismantling Joints These joints feature flanges at both ends, allowing for easy connection to other flanged fittings. They are particularly useful in systems where accessibility and frequent maintenance are required.

pipe dismantling joint

2. Mechanical Dismantling Joints This type uses a combination of bolts and seals to connect pipe sections. They allow for easy accessibility but require careful monitoring to ensure that all connections remain sealed.

3. Flexible Dismantling Joints These joints incorporate flexible components that not only allow for easy removal but also accommodate minor movements and vibrations within the system.

Installation of Dismantling Joints

The installation process for dismantling joints is relatively straightforward but requires careful planning and execution to ensure optimal performance. Here are key steps in the installation process

1. Preparation Before installation, the pipeline must be cleaned and inspected for any damage. Accurate measurements of the pipe diameter and length are also necessary.

2. Positioning Dismantling joints should be installed in a location that allows for easy access. This placement is critical for future maintenance.

3. Alignment Proper alignment with the connecting pipes is essential to avoid undue stress on the joints and surrounding fittings.

4. Securing Once aligned, joints are bolted as per manufacturer's specifications. All fasteners should be torqued to the recommended level to ensure a secure fit.

Maintenance of Dismantling Joints

Regular maintenance is crucial to the longevity of dismantling joints. Here are maintenance best practices

1. Routine Inspections Regular checks for signs of leaks, wear, and misalignment can help identify potential issues before they escalate.

2. Tightening Connections Periodic tightening of bolts and connections, according to standards, ensures continued effectiveness.

3. Cleaning Keeping the exterior and surrounding areas clean can prevent the buildup of corrosive materials that might affect the integrity of the joints.

In conclusion, pipe dismantling joints play a vital role in the functionality and efficiency of pipeline systems. With their ability to simplify maintenance and reduce costs, they are indispensable in a wide range of applications. Understanding their types, benefits, and proper maintenance can greatly enhance the reliability of any piping network. Implementing proper installation and maintenance practices ensures that dismantling joints perform optimally over the life of the pipeline system.

Share

-

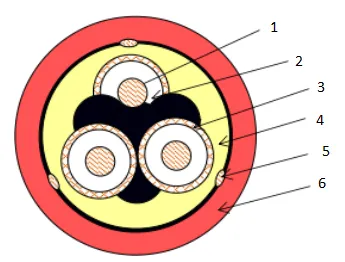

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025