Ліст . 22, 2024 20:20 Back to list

double plate check valve

Understanding Double Plate Check Valves

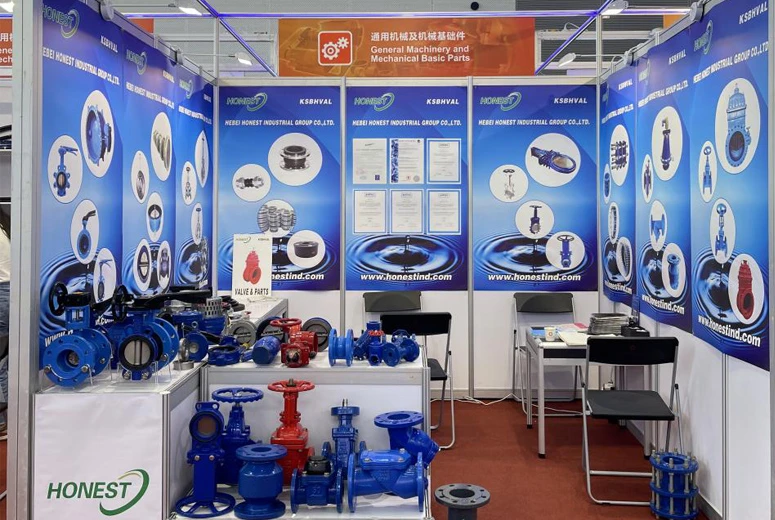

Double plate check valves are essential components in various piping systems, particularly in water and wastewater management, as well as in industrial applications. These valves are designed to prevent backflow in a system, ensuring that the flow of fluid proceeds in one direction only. This is crucial for protecting pumps, compressors, and other critical equipment from the damaging effects of reverse flow.

The design of double plate check valves consists of two plates that are hinged together. When fluid flows in the intended direction, the plates open, allowing the fluid to pass through. However, if there is a reverse flow, the plates close tightly against the valve seat, effectively blocking the flow and preventing any potential damage or contamination. This mechanism not only provides a reliable seal but also minimizes the potential for leaks.

One of the key advantages of double plate check valves is their lightweight and compact design. Unlike traditional swing check valves, which can be bulky and heavy, double plate check valves are significantly easier to install and require less space in piping systems. This makes them an ideal choice for applications with limited installation space or where weight is a consideration.

double plate check valve

In addition to their efficiency and space-saving benefits, double plate check valves also offer a relatively low pressure drop compared to other check valve designs. This is particularly important in systems where maintaining pressure is critical. By minimizing pressure losses, double plate check valves help optimize the overall efficiency of the fluid system.

Moreover, these valves are versatile and can be manufactured from various materials such as stainless steel, carbon steel, and plastic. This allows for customization based on the specific requirements of the fluid being transported and the operating conditions of the system, such as temperature and pressure.

Maintenance of double plate check valves is straightforward. Regular inspections can help monitor for wear and tear or any buildup that may affect their performance. Ensuring they are in good condition contributes to the longevity and reliability of the entire piping system.

In conclusion, double plate check valves are a vital part of fluid control systems, offering reliable backflow prevention with numerous advantages. Their compact design, low pressure drop, and versatility make them a preferred choice for many applications, ensuring the safety and efficiency of numerous industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025