снеж . 06, 2024 16:57 Back to list

cast iron y strainer

The Essential Role of Cast Iron Y Strainers in Industrial Applications

Cast iron Y strainers are an indispensable component in many industrial applications, effectively ensuring the smooth operation of pipelines and machinery. These robust devices are designed to filter out unwanted debris and contaminants from fluids, protecting pumps, valves, and other critical equipment from potential damage. In this article, we will explore the design, functionality, and advantages of cast iron Y strainers while understanding why they have become a preferred choice in various sectors.

What is a Cast Iron Y Strainer?

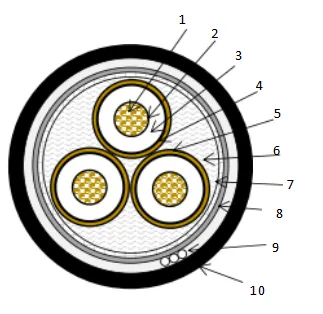

A Y strainer, characterized by its distinctive Y shape, is a type of strainer used to separate particulate matter from liquid pipelines. The design features an inlet and outlet aligned in a Y configuration, allowing for easy installation within the pipeline while maintaining a compact profile. The strainer is typically equipped with a mesh filter element that captures debris as fluid flows through, ensuring that only clean fluid continues downstream. Cast iron is commonly used for the construction of Y strainers due to its excellent durability, corrosion resistance, and ability to withstand high pressure and temperature.

Functionality of Y Strainers

The primary function of a cast iron Y strainer is to filter out any solid impurities present in the fluid. These impurities can range from rust particles and dirt to larger debris, all of which can cause significant operational issues if allowed to enter machinery or systems. By employing a Y strainer in a fluid system, operators can prevent clogs and damage that could lead to costly repairs and downtime.

The strainer operates by allowing the fluid to enter through the inlet, pass through the mesh filter, and exit via the outlet. As the fluid flows, larger particles are trapped within the filter element, while clean fluid moves downstream. After a period of operation, the strainer may become clogged and require cleaning or replacement of the filter element. Most cast iron Y strainers are designed with a convenient blow-off valve, allowing for easy maintenance with minimal disruption to the workflow.

Advantages of Cast Iron Y Strainers

cast iron y strainer

1. Durability and Strength Cast iron is favored for its tensile strength and resistance to wear and tear, making Y strainers highly durable in demanding environments. They can tolerate high pressure and temperature, making them suitable for various applications, including steam, water, oil, and gas systems.

2. Corrosion Resistance While cast iron is prone to rust, modern coatings and the use of high-quality cast iron alloys can significantly enhance corrosion resistance, ensuring a longer lifespan for the strainer.

3. Versatile Applications Cast iron Y strainers are used across diverse industries such as oil and gas, chemical processing, power generation, and water treatment. Their adaptability makes them essential for maintaining the integrity of various fluid systems.

4. Cost-Effectiveness The longevity and durability of cast iron Y strainers translate into lower maintenance costs over time. By preventing equipment damage and system failures, they contribute to more efficient and cost-effective operations.

5. Ease of Maintenance With features like a blow-off valve, cast iron Y strainers are designed for easy access and cleaning. This simplicity reduces the labour and time involved in maintaining system efficiency.

Conclusion

In summary, cast iron Y strainers play a critical role in maintaining clean and efficient fluid systems within various industries. Their robust design, corrosion resistance, and ease of maintenance make them a preferred choice for filtering applications. By investing in quality Y strainers, businesses can protect their machinery, reduce operational costs, and ensure the reliability of their operations. As industries continue to evolve, the importance of these essential components will only grow, highlighting the need for reliable filtration solutions in modern fluid management systems.

Share