Sen . 03, 2024 07:16 Back to list

Y Strainer ANSI 150 - High-Performance Filtration Solutions

Understanding Y Strainers with ANSI 150 Standards

Y strainers are essential components in various piping systems, primarily used to filter out unwanted solid particles from liquids or gases. By doing so, they protect downstream equipment from damage and ensure operational efficiency. Among the different standards that guide the design and manufacturing of Y strainers, the ANSI 150 specifications are particularly significant.

Understanding Y Strainers with ANSI 150 Standards

One of the vital aspects of the ANSI 150 standard is the pressure rating. The ANSI 150 class typically signifies that the equipment can handle a maximum pressure of 150 psi (pounds per square inch) at a temperature of 100°F. This rating is crucial for engineers and designers when selecting components for specific applications, as it ensures that the Y strainer can operate safely within the required pressure limits.

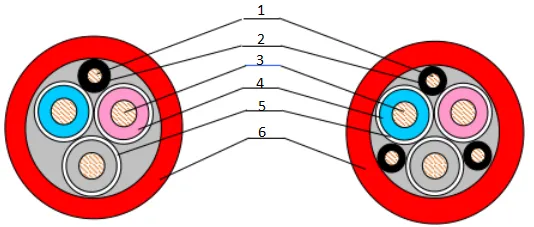

y strainer ansi 150

Material selection is another critical factor covered by ANSI standards. Y strainers can be made from a variety of materials, such as cast iron, bronze, stainless steel, or carbon steel, depending on the fluid being filtered and the environment of operation. For instance, stainless steel Y strainers are highly recommended for corrosive applications due to their resistance to oxidation and corrosion, while bronze strainers are often used in potable water applications.

The design of Y strainers also adheres to ANSI guidelines, which define the dimensions and construction requirements. A standard Y strainer features a Y-shaped body that allows for a compact installation and easy access for maintenance. The strainer’s mesh or perforated screen captures debris, and the design ensures that the pressure drop across the strainer remains minimal, thereby maintaining the flow rate within the system.

Installation and maintenance considerations are crucial in maximizing the performance of Y strainers. Proper installation involves ensuring that the strainer is oriented correctly within the piping system, typically with the screen positioned in a horizontal plane for optimal flow and debris capture. Regular maintenance is necessary to clean or replace the strainer element, preventing blockages that can lead to increased pressure drops and potential system failures.

In conclusion, Y strainers that conform to the ANSI 150 standard play a vital role in industrial applications by ensuring the integrity and longevity of piping systems. By adhering to these guidelines for pressure ratings, materials, dimensions, and installation, facilities can protect their equipment against harmful debris, ultimately enhancing operational efficiency and reliability. Understanding the significance of ANSI 150 standards in the context of Y strainers is essential for anyone involved in the design or maintenance of piping systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025