Dek . 12, 2024 20:20 Back to list

mss metal seat gate valve

Understanding MSS Metal Seat Gate Valves

Gate valves are critical components in various industrial applications, primarily used to control the flow of liquids and gases. Among the different types of gate valves, MSS (Manufacturers Standardization Society) metal seat gate valves are prominent due to their durability and reliability. This article aims to explore the characteristics, advantages, applications, and maintenance of MSS metal seat gate valves.

Characteristics of MSS Metal Seat Gate Valves

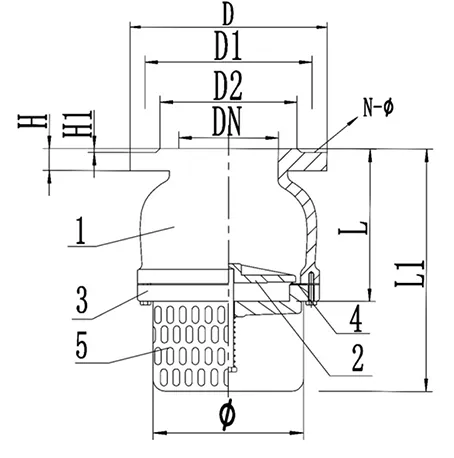

MSS metal seat gate valves are designed to provide excellent sealing capabilities. The defining feature of metal seat valves is their metal-to-metal sealing mechanism, which is achieved through the use of a hardened metal seat and a wedge gate. This design ensures that the valve can maintain a tight seal under various pressures and temperatures, making it suitable for challenging environments.

These valves are manufactured according to the stringent standards set by the Manufacturers Standardization Society, ensuring consistency and quality across all units. They are typically constructed from high-quality materials such as stainless steel, carbon steel, or alloy steel, which enhances their strength and resistance to corrosion. The inclusion of these robust materials ensures that MSS metal seat gate valves can withstand the rigors of industrial applications, including those involving corrosive substances.

Advantages of MSS Metal Seat Gate Valves

One of the primary advantages of MSS metal seat gate valves is their ability to handle high-pressure applications. The metal seating surface allows these valves to achieve a leak-tight seal, which is essential in processes where fluid containment is critical. Additionally, the durability of the metal seat enables the valve to perform effectively even after extensive use, reducing the frequency of replacements and repairs.

Another significant benefit is their resistance to thermal variations. Metal seat gate valves can operate effectively in both high-temperature and low-temperature environments, making them suitable for oil and gas applications, steam systems, and waterworks. This versatility ensures that they can be used across a wide range of industries, including petrochemical, mining, and power generation.

Moreover, MSS metal seat gate valves are designed for straightforward operation. Their simple open-and-close mechanism requires minimal effort, allowing for quick and efficient control of flow. This user-friendly feature is particularly advantageous in emergency situations where rapid valve operation may be necessary.

mss metal seat gate valve

Applications of MSS Metal Seat Gate Valves

MSS metal seat gate valves are employed in numerous applications across various industries. In the oil and gas sector, they are commonly used to manage the flow of crude oil, natural gas, and other materials within pipelines. Their robust construction and reliable sealing capabilities make them an ideal choice for such demanding applications.

In the water treatment industry, these valves are essential for controlling the flow of water in treatment plants and distribution systems. Their ability to maintain a leak-tight seal is crucial for preventing loss of treated water and ensuring that contaminants do not enter the system.

Additionally, MSS metal seat gate valves find application in power generation facilities. They are utilized in steam lines, cooling water systems, and various other processes where flow control is essential. The ability to operate under high pressures and temperatures further solidifies their role in this industry.

Maintenance of MSS Metal Seat Gate Valves

Maintaining MSS metal seat gate valves is essential to ensure their longevity and optimal performance. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. Any debris or foreign materials should be cleared from the valve seat to prevent leaks and ensure smooth operation.

Lubrication of the valve stem and other moving components is also crucial in maintaining operational efficiency. This practice minimizes friction and prevents premature wear of the valve parts. Additionally, operators should familiarize themselves with the specific maintenance guidelines provided by the valve manufacturer to ensure adherence to best practices.

Conclusion

In conclusion, MSS metal seat gate valves are integral components in various industrial applications due to their reliability, durability, and performance under high-pressure conditions. Understanding their characteristics, advantages, applications, and maintenance requirements is essential for ensuring effective flow control in demanding environments. As industries continue to evolve, the role of these valves will remain pivotal in maintaining the efficient operation of fluid systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025