Dek . 01, 2024 20:52 Back to list

full lug butterfly valve

Understanding Full Lug Butterfly Valves A Comprehensive Overview

When it comes to industrial plumbing and fluid management, valves play a crucial role in controlling the flow of liquids and gases. Among the various types of valves available, the full lug butterfly valve has gained significant popularity due to its unique design, ease of use, and efficiency in various applications. This article will delve into the features, benefits, applications, and maintenance of full lug butterfly valves.

What is a Full Lug Butterfly Valve?

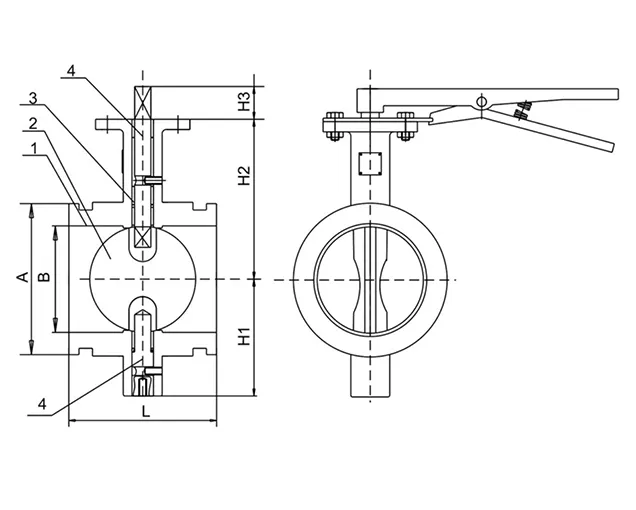

A full lug butterfly valve is a quarter-turn valve that consists of a rotating disc or disc-like component, which regulates the flow of fluid through a pipeline. The term 'full lug' refers to the design of the valve’s body, which is equipped with lugs or protruding sections that facilitate easy mounting and dismounting. These lugs allow the valve to be bolted directly to the piping, providing sturdy support and ensuring tight sealing. Unlike standard butterfly valves, full lug valves can be installed in-line or at the end of a piping system, making them highly versatile.

Key Features of Full Lug Butterfly Valves

1. Compact Design Full lug butterfly valves are often more compact than other valve types, making them suitable for applications with space constraints.

2. Lightweight Made from materials such as aluminum, plastic, and stainless steel, these valves are lightweight, which facilitates easy handling and installation.

3. Quick Operation The quarter-turn operation allows for rapid opening and closing, making these valves ideal for applications that require fast flow regulation.

4. Resistance to Corrosion Many full lug butterfly valves are designed to resist corrosion, making them suitable for use in various industries, including water treatment, chemicals, and food processing.

5. Versatile Installation Due to the full lug feature, these valves can be installed in different orientations and piping configurations, providing flexibility in design.

Benefits of Full Lug Butterfly Valves

- Cost-Effective Compared to other valve types, full lug butterfly valves are generally more affordable. Their simple design and construction also make them easy to maintain and replace, further reducing costs over time.

- Effective Flow Control The design of the valve allows for smooth flow regulation, minimizing turbulence and pressure drops. This property is crucial in applications that require precise flow measurement.

- Durability With fewer moving parts than traditional valves, full lug butterfly valves tend to exhibit greater durability. This longevity translates into lower replacement and maintenance costs.

- Ease of Maintenance Maintenance procedures for full lug butterfly valves are typically straightforward, requiring minimal tools and expertise to perform routine checks or replacements

.full lug butterfly valve

Common Applications

Full lug butterfly valves are widely used across various industries due to their efficiency and adaptability. Some common applications include

1. Water and Wastewater Treatment These valves are ideal for managing flow rates and controlling the distribution of water in treatment facilities.

2. Chemical Processing In chemical handling, where corrosive fluids are prevalent, full lug butterfly valves provide reliable isolation and regulation.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these valves are used to control air and fluid flow.

4. Food and Beverage Industry The non-toxic materials and corrosion resistance make full lug butterfly valves suitable for food and beverage applications, ensuring product safety.

5. Pulp and Paper Industry The ability to handle fibrous materials and aggressive chemicals makes them valuable in pulp and paper manufacturing.

Maintenance Tips

To ensure the optimal performance and longevity of full lug butterfly valves, regular maintenance is essential. Here are some tips

- Regular Inspection Check for signs of wear or damage, particularly around the sealing surfaces and the disc.

- Lubrication If applicable, periodically lubricate moving parts to ensure smooth operation.

- Cleaning Keep the valve free of debris and impurities that could impede its function.

- Testing Conduct routine tests to check for leaks or any irregular flow patterns.

Conclusion

Full lug butterfly valves serve as efficient, cost-effective solutions for controlling fluid and air flow across various industries. Their durable construction, ease of maintenance, and versatility make them an excellent choice for many applications. By understanding their features, benefits, and maintenance requirements, industry professionals can make informed decisions about implementing these crucial components in their systems. As technology continues to evolve, full lug butterfly valves will undoubtedly remain a staple in fluid management solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025