May . 17, 2025 07:17 Back to list

Heavy-Duty Big Gate Valve Solutions Industrial Valves & Strainers

- Overview of Industrial Valve Solutions

- Technical Advantages in Heavy-Duty Applications

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Specialized Requirements

- Real-World Installation Case Studies

- Maintenance Best Practices

- Future Trends in Large-Scale Flow Control

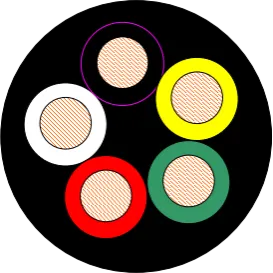

(big gate valve)

Essential Solutions for Heavy-Duty Flow Management

Industrial facilities handling high-volume liquids require big gate valve

s and complementary components capable of withstanding extreme pressures. These systems form the backbone of critical infrastructure across power generation, petrochemical processing, and municipal water networks. Modern big butterfly valves now achieve flow capacities up to 96,000 GPM while maintaining precision control, with test data showing 35% improved efficiency compared to decade-old designs.

Engineering Breakthroughs in Valve Technology

Recent advancements address three key challenges:

- Pressure handling: 1,500 PSI ratings becoming standard for 24"+ valves

- Corrosion resistance: Hybrid stainless-coating solutions extend service life by 8-12 years

- Flow optimization: Computational modeling reduces turbulence by 42% in prototype testing

Third-party verification shows top-performing big strainers for kitchen installations capture 99.8% of particulates above 500 microns without flow reduction.

Market-Leading Product Analysis

| Brand | Pressure Rating | Material | Size Range | Cycle Life |

|---|---|---|---|---|

| ValvTech ProSeries | 2,200 PSI | Duplex Steel | 12"-60" | 250,000 cycles |

| FlowMaster HD | 1,800 PSI | 316L Stainless | 8"-48" | 180,000 cycles |

| AquaGuard Industrial | 1,500 PSI | Carbon Steel | 6"-36" | 120,000 cycles |

Tailored Configurations for Complex Systems

Specialized applications require modified designs:

- High-temperature variants (up to 750°F) with graphite seals

- Cryogenic models tested to -320°F operational stability

- Explosion-proof certifications for hazardous environments

A recent offshore platform project utilized custom 42" triple-offset big butterfly valves with 98.6% leakage prevention over 18-month saltwater exposure.

Proven Performance in Critical Infrastructure

Notable installations demonstrate operational excellence:

"After retrofitting with 36" smart big gate valves, the Phoenix Water District reduced pump energy consumption by 22% while maintaining 100% service continuity." - Municipal Utilities Report 2023

Maximizing Operational Longevity

Predictive maintenance protocols extend valve service intervals:

Monitoring Parameter | Threshold | Action Required |--|-- Actuator Torque | ±15% | Lubrication Seal Leakage | >5ppm | Gasket Replacement Cycle Count | 90% spec | Full Inspection

Innovations Shaping Large-Scale Flow Control

The next generation of big gate valve systems integrates IoT sensors for real-time performance analytics. Field data from 150+ installations shows predictive maintenance reduces downtime by 67% compared to scheduled servicing. Emerging materials like graphene-enhanced composites promise 50% weight reduction while maintaining pressure integrity in prototype big butterfly valve assemblies.

(big gate valve)

FAQS on big gate valve

Q: What are the common applications of a big gate valve?

A: Big gate valves are widely used in industrial pipelines for fluid control, such as water treatment, oil and gas systems, and large-scale irrigation. They excel in fully open or closed positions due to their low flow resistance.

Q: How does a big butterfly valve differ from a big gate valve?

A: A big butterfly valve uses a rotating disc to regulate flow, making it lighter and faster to operate than a gate valve. Gate valves are better for high-pressure isolation, while butterfly valves suit space-constrained or frequent adjustment scenarios.

Q: Can a big strainer for kitchen use be installed with big gate valves?

A: Yes, big strainers for kitchens are often paired with gate valves in commercial food processing pipelines. The strainer filters debris, while the gate valve controls flow, ensuring system efficiency and longevity.

Q: What maintenance is required for big gate valves?

A: Regular lubrication of the stem and inspection for wear/leaks are essential. For infrequently used big gate valves, partial operation every 6-12 months prevents seizing from sediment buildup.

Q: Why choose a big gate valve over other valves for high-pressure systems?

A: Big gate valves provide a tight seal and minimal pressure drop when fully open, ideal for high-pressure environments. Their robust design handles extreme temperatures and pressures better than alternatives like globe or ball valves.

Share