سبتمبر . 07, 2024 17:24 Back to list

Low Pressure Check Valve - Reliable Flow Control Solutions

Understanding Low Pressure Check Valves

Low pressure check valves play a crucial role in various industrial and engineering applications. These devices are designed to allow fluid flow in one direction while preventing backflow. Their primary function is to maintain the integrity of a system by ensuring that fluids do not reverse course, which can cause significant damage or inefficiency.

Check valves are typically found in systems where pressure may fluctuate or where backflow could introduce contaminants. In low-pressure systems, these valves help ensure that even slight changes in pressure do not compromise the flow direction. This is particularly important in processes involving delicate materials or chemical reactions that could be adversely affected by backflow.

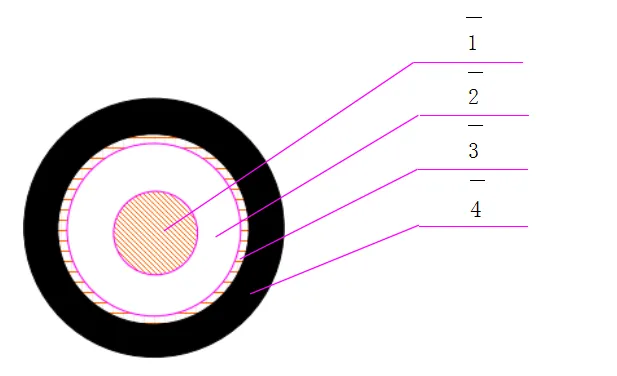

One of the key features of low pressure check valves is their simple yet effective design. Most consist of a valve body with a disc or ball that opens to allow flow in the desired direction and closes under reverse pressure to block backflow. The materials used in manufacturing these valves, such as plastic, brass, or stainless steel, are selected based on compatibility with the fluids they will encounter and the environment in which they will operate.

low pressure check valve

In applications like water treatment, food processing, and HVAC systems, low pressure check valves help maintain efficient flow rates and ensure safety. For instance, in a water supply system, a check valve prevents water from flowing backward into the supply source, thereby protecting it from potential contamination. Similarly, in heating systems, they keep hot water from returning to the boiler, ensuring that the system operates efficiently.

The selection of the right low pressure check valve involves considering various factors, including the fluid type, temperature, and pressure conditions. It's crucial to choose a valve that not only fits the specific parameters of the system but also offers durability and reliability. Maintenance is also vital; while these valves typically require minimal upkeep, regular inspections can prevent issues before they arise.

In conclusion, low pressure check valves are integral components in ensuring the smooth operation of various fluid systems. Their ability to prevent backflow protects equipment, maintains flow efficiency, and ensures the quality of the fluids being transported. As industries continue to evolve and demand more reliable solutions, the importance of these valves will only increase, highlighting their role in modern engineering and industrial applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025