ታኅሣ . 21, 2024 23:54 Back to list

lift check valve

Understanding Lift Check Valves Functionality and Applications

Introduction

Lift check valves are a vital component in various hydraulic and pneumatic systems, designed to allow fluid to flow in one direction while preventing backflow. Their simplicity, reliability, and efficiency make them a popular choice in many industrial applications, from water supply systems to sophisticated air compression setups. This article delves into the functionality, design, applications, and benefits of lift check valves.

What is a Lift Check Valve?

A lift check valve is a type of valve that utilizes a disc and a seat to control the flow of fluid. Unlike other check valves, lift check valves rely on the movement of the disc along the valve shaft to open and close. When fluid flows in the correct direction, the pressure forces the disc upward, allowing the fluid to pass through. If the flow reverses, the disc will fall back onto the seat, creating a seal that prevents backflow.

Design and Operation

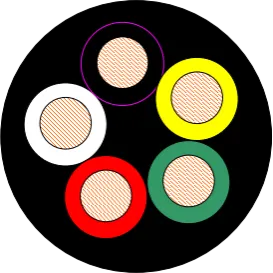

The design of lift check valves is crucial for their operation. Typically made from materials like brass, stainless steel, or plastic, these valves consist of several key components

1. Body The outer casing that houses all internal components and connects to the piping system. 2. Disc The critical moving part that lifts to allow fluid flow. Its design can vary, but it is usually circular and shaped for optimal sealing. 3. Seat The surface against which the disc seals when backflow occurs. A well-machined seat ensures a tight seal to prevent leaks. 4. Spring (Optional) Some designs incorporate a spring mechanism that aids in closing the valve quickly, enhancing the valve's responsiveness to changes in flow direction.

The operation of a lift check valve is simple yet effective, relying on the principles of fluid dynamics and pressure differentials. When fluid flows in the intended direction, the pressure lifts the disc. If the flow decreases or reverses, the inherent weight of the disc combined with any spring tension quickly returns it to the closed position.

Applications

Lift check valves find applications across a broad spectrum of industries, including

lift check valve

- Water and Wastewater Management These valves are critical in municipal and industrial water systems to prevent backflow, protecting water quality and system integrity. - Oil and Gas In the extraction and transportation of hydrocarbons, lift check valves help manage fluid movement in pipelines, ensuring that oil and gas flow in the desired direction. - HVAC Systems In heating, ventilation, and air conditioning systems, these valves regulate the flow of refrigerants and facilitate efficiency in thermal management. - Pneumatic Systems In systems that utilize compressed air, lift check valves control airflow, preventing backsurge that could damage equipment or disrupt processes.

Advantages of Lift Check Valves

The use of lift check valves offers several advantages

1. Prevention of Backflow Lift check valves effectively prevent the backflow of fluids, which can lead to contamination or system damage.

2. Minimal Pressure Loss Their design allows for relatively low resistance to flow, ensuring efficient system operation.

3. Durability With proper maintenance, lift check valves are long-lasting and can withstand varying pressure and temperature conditions.

4. Versatility Available in various materials and sizes, lift check valves can be tailored to meet specific application needs.

5. Ease of Maintenance The straightforward design of many lift check valves allows for easy repair or replacement without significant downtime.

Conclusion

In summary, lift check valves are an essential component in various industrial systems, providing reliable and efficient control of fluid flow. Their design simplicity, combined with their effectiveness in preventing backflow, makes them a preferred choice in many applications. Understanding the functionality and benefits of lift check valves can help engineers and system designers make informed decisions that enhance system efficiency and longevity. As industries continue to evolve, the significance of such components will undoubtedly endure, driving advancements in fluid management technologies.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025