ኅዳር . 08, 2024 06:07 Back to list

Flange Adapters and Dismantling Joints for Efficient Pipeline Connections and Maintenance Solutions

Flange Adaptors and Dismantling Joints Essential Components for Efficient Pipeline Systems

Flanged connections are the backbone of many industrial piping systems, providing a reliable method to connect pipes, valves, and other equipment. Among these connections, flange adaptors and dismantling joints play significant roles, facilitating easy installation, maintenance, and flexibility within pipeline networks. This article will delve into their functions, benefits, and applications in various industries.

Flange Adaptors Bridging the Gap in Piping Systems

Flange adaptors are specialized fittings designed to connect pipes with different flange types, sizes, or materials. They serve as an interface between two disparate piping systems, allowing for seamless integration. For instance, a flange adaptor can connect a cast iron pipe to a plastic pipe, accommodating variations in size and ensuring a secure and leak-free connection.

One of the primary advantages of using flange adaptors is their ability to simplify the installation process. Instead of needing to fabricate custom fittings or engage in complex welding procedures, a flange adaptor provides a quick and efficient solution. This not only saves time but also reduces labor costs and minimizes the risk of errors during installation.

Moreover, flange adaptors come in various designs to suit different applications. They can be manufactured with rubber seals or gaskets that ensure a tight fit, preventing leakage and enhancing the longevity of the joint. The versatility of flange adaptors makes them an ideal choice for water supply systems, wastewater treatment plants, and industrial pipelines where fluid types and pressures can vary significantly.

Dismantling Joints Enhancing Maintenance and Flexibility

In addition to flange adaptors, dismantling joints are another critical component in modern piping systems. These joints facilitate the easy disassembly of piping sections, making maintenance and repairs much more manageable. A dismantling joint allows operators to remove, replace, or adjust pipes without needing to cut or disturb the surrounding infrastructure.

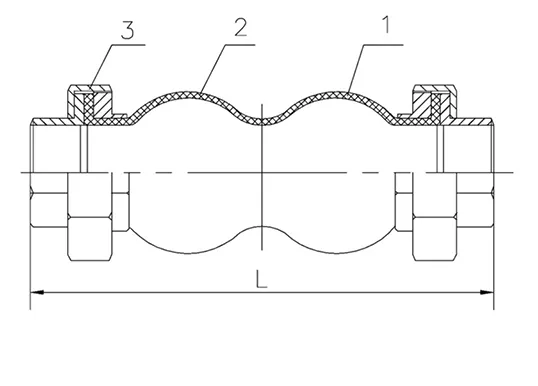

flange adaptor and dismantling joint

The design of dismantling joints typically includes an integral flange that connects to the pipeline, along with adjustable bolts that allow for controlled deformation. This feature is particularly beneficial in systems where frequent maintenance is required, such as in water treatment facilities or power plants. By utilizing dismantling joints, operators can significantly reduce downtime during repairs, thereby enhancing the overall efficiency of the operation.

Furthermore, dismantling joints provide vital flexibility in a pipeline system. They allow for adjustments to be made in the piping layout without the need for extensive rework. For example, if modifications are needed due to changing operational requirements or space constraints, a dismantling joint can facilitate these changes with ease.

Applications Across Industries

Flange adaptors and dismantling joints find applications across various sectors, ranging from municipal water supply to heavy industry. In municipal water systems, these components are invaluable for connecting pipes of varying materials and dimensions, ensuring a consistent flow of water to homes and businesses. In wastewater management, dismantling joints enable easy access for routine inspections and emergency repairs, essential for maintaining optimal system performance.

In industrial settings, such as petrochemical plants or manufacturing facilities, flange adaptors facilitate connections between different equipment. They help manage the transportation of diverse fluids, including gases, liquids, and slurries. Their ability to handle high pressures and corrosive materials makes them crucial for safe and reliable operations.

Conclusion

In conclusion, flange adaptors and dismantling joints are indispensable elements in the design and operation of modern piping systems. Their capacity to bridge the gap between different pipe types and facilitate easy maintenance enhances the efficiency, safety, and longevity of industrial applications. As industries continue to evolve and demand more robust and flexible piping solutions, the importance of these components will only grow. Investing in quality flange adaptors and dismantling joints ensures that pipelines can adapt to changing needs without sacrificing performance or reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025