ኅዳር . 17, 2024 13:04 Back to list

butterfly check valve

Understanding Butterfly Check Valves Function, Design, and Applications

Butterfly check valves are essential components in various fluid systems, known for their unique design and operational efficiency. These valves are primarily designed to allow fluid flow in one direction while preventing backflow, ensuring the protection and integrity of piping systems. In this article, we will explore the fundamental aspects of butterfly check valves, including their design, functionality, advantages, and typical applications.

What is a Butterfly Check Valve?

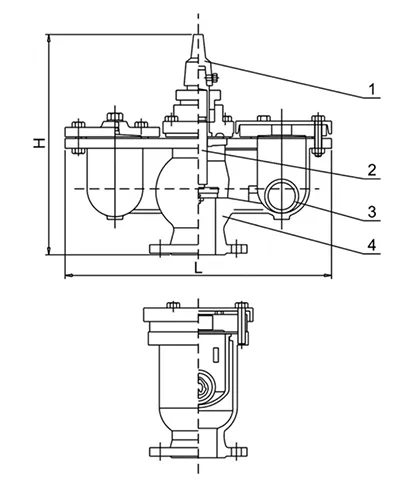

A butterfly check valve is a type of valve that incorporates a rotating disc to regulate flow. The disc, resembling a butterfly's wings, is mounted on a shaft, which is either parallel or perpendicular to the flow direction. When fluid flows in the intended direction, the disc swings open, allowing flow. Conversely, if there is a backflow, the pressure forces the disc to pivot and close, effectively blocking the reverse flow.

Design and Functionality

The design of butterfly check valves is relatively simple, which contributes to their popularity in various industries. They are typically made from durable materials, such as cast iron, stainless steel, or PVC, depending on the specific application and environmental conditions.

One of the key features of these valves is their low profile, allowing for compact installation in systems where space is limited. The disc rotation requires minimal force, which translates to lower operational pressures and energy consumption compared to other valve types. Some butterfly check valves incorporate spring mechanisms that assist in closing the disc quickly and securely, enhancing their effectiveness in preventing backflow.

Another advantage of butterfly check valves is their ability to handle a wide range of fluid types, including water, chemicals, and gases. Their versatility makes them suitable for various applications across different industries.

Advantages of Butterfly Check Valves

2. Lightweight Given their design and materials, butterfly check valves are often lighter than other types of valves. This reduces installation costs and makes them easier to handle during maintenance.

3. Efficiency The disc's design minimizes pressure drop, promoting efficient fluid flow. This characteristic is particularly advantageous in systems where energy conservation is a priority.

butterfly check valve

4. Low Maintenance Butterfly check valves generally require less maintenance than other valve types, which can lead to lower operational costs over time. Their simple construction makes inspections straightforward.

5. Wide Application Range These valves can be used in numerous applications, from water treatment facilities to industrial processes and HVAC systems, thanks to their adaptability to various media.

Applications of Butterfly Check Valves

Butterfly check valves are used in a diverse range of sectors, reflecting their versatility. Some common applications include

- Water Supply Systems Used in municipal and industrial water distribution systems to prevent backflow and ensure clean water supply.

- Oil and Gas Industries These valves help manage fluid flow in pipelines, ensuring safe operations while preventing contamination.

- HVAC Systems In heating, ventilation, and air conditioning applications, butterfly check valves regulate flow and maintain system efficiency.

- Chemical Processing In chemical plants, these valves control the flow of corrosive substances while ensuring safety by preventing backflow.

- Pumping Stations Butterfly check valves are often installed in pumping systems to maintain pressure and flow direction, protecting pumps from damage caused by backpressure.

Conclusion

Butterfly check valves play a crucial role in various fluid handling systems, providing reliable performance and versatility. Their compact design, combined with a range of operational advantages, positions them as a preferred choice in numerous applications. As industries continue to evolve and seek efficient solutions for fluid management, the importance of butterfly check valves is likely to grow, highlighting their significance in maintaining system integrity and operational efficiency. Understanding their function, design, and applications can help engineers and operators make informed decisions when selecting valves for their specific needs.

Share

-

YType Strainer: Reliable guardians in fluid pipelinesNewsMay.15,2025

-

Wire Cable: The invisible pillar of engineering strengthNewsMay.15,2025

-

Wafer Type Butterfly Valve Flange: Characteristics, Applications, and Development TrendsNewsMay.15,2025

-

Standard Wire and Cable: Building the nervous system of modern societyNewsMay.15,2025

-

RSV Gate Valves: Structure, Application, and Analysis of Advantages and DisadvantagesNewsMay.15,2025

-

NonReturn Swing Check Valve: A reliable unidirectional flow control deviceNewsMay.15,2025