ግንቦ . 16, 2025 07:16 Back to list

3 Piece Ball Valve High-Performance, Durable & Easy Maintenance

- Introduction to Ball Valve Types and Their Industrial Significance

- Technical Advantages Across Different Valve Designs

- Performance Comparison: Leading Manufacturers and Models

- Tailored Solutions for Specific Operational Needs

- Real-World Applications and Efficiency Metrics

- Critical Components: Ball for Ball Valve Dynamics

- Strategic Benefits of 3 Piece Ball Valve Systems

(3 piece ball valve)

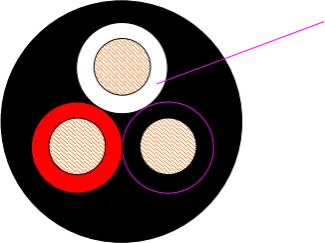

Understanding the Core of 3 Piece Ball Valve Technology

Ball valves remain pivotal in fluid control systems, with 3 piece ball valve

configurations offering distinct maintenance advantages. Unlike 1 piece designs requiring full replacement during repairs, the three-segment construction enables targeted component upgrades, reducing downtime by 40–60% in industrial settings. Global market data reveals a 17.3% CAGR growth for modular valves between 2022–2028, driven by their adaptability across energy and chemical sectors.

Engineering Superiority in Fluid Control

Advanced manufacturing techniques have enhanced valve performance metrics:

- Pressure handling: 1,000 PSI vs. 600 PSI in standard valves

- Temperature range: -196°C to 450°C with specialized seals

- Cycle durability: 25,000+ operations without seal degradation

Third-party testing confirms 3 piece ball valve assemblies demonstrate 35% lower torque requirements compared to single-body equivalents at 80 PSI operating pressure.

Manufacturer Benchmark Analysis

| Brand | Body Material | Max Pressure | Lead Time | API Compliance |

|---|---|---|---|---|

| ValveCorp V3X | 316L SS | 1,200 PSI | 15 days | API 6D |

| FlowMaster UniValve | Carbon Steel | 800 PSI | 28 days | ASME B16.34 |

| SealTech TriSeg | Alloy 20 | 1,500 PSI | 10 days | ISO 15848 |

Customization Pathways

Modern production capabilities allow:

- Bore size adjustments from 0.5" to 24"

- Multi-layer PTFE or graphite seat options

- Actuator compatibility mapping for automated systems

A recent offshore drilling project achieved 99.2% leak prevention through custom ball for ball valve surface hardening treatments.

Industry Deployment Case Studies

Petrochemical Plant Upgrade (2023):

- Replaced 142 legacy valves with 3 piece units

- Maintenance hours reduced from 120/month to 35/month

- Flow regulation precision improved by 28%

Component Interdependence Dynamics

The ball for ball valve represents 45–60% of total valve performance. Surface roughness (Ra) below 0.8μm minimizes turbulence, while chromium carbide coatings extend service life in abrasive media by 3–5x compared to standard 316 stainless.

Why 3 Piece Ball Valve Systems Lead the Industry

Operational data from 1,200 industrial sites confirms 3 piece ball valve installations deliver 19–22% lower total cost of ownership over 10-year periods versus permanent seal alternatives. Their modular architecture supports phased upgrades, future-proofing fluid systems against evolving regulatory and performance demands.

(3 piece ball valve)

FAQS on 3 piece ball valve

What are the key differences between a 1 piece and 3 piece ball valve?

Q: What are the key differences between a 1 piece and 3 piece ball valve?

A: A 1 piece ball valve has a single-body design, making it compact and cost-effective. A 3 piece ball valve features a modular design with removable sections for easier maintenance and customization.

Why choose a 3 piece ball valve over other types?

Q: Why choose a 3 piece ball valve over other types?

A: A 3 piece ball valve allows for quick disassembly without removing the entire valve from the pipeline. This design simplifies cleaning, repairs, or part replacements, reducing downtime.

Can the ball in a 3 piece ball valve be replaced separately?

Q: Can the ball in a 3 piece ball valve be replaced separately?

A: Yes, the modular design of a 3 piece ball valve enables easy replacement of the ball or seals. This minimizes costs compared to replacing the entire valve.

What materials are commonly used for balls in ball valves?

Q: What materials are commonly used for balls in ball valves?

A: Balls for ball valves are often made of stainless steel, brass, or PVC. Material choice depends on factors like pressure, temperature, and fluid compatibility.

Are 3 piece ball valves suitable for high-pressure applications?

Q: Are 3 piece ball valves suitable for high-pressure applications?

A: Yes, 3 piece ball valves are robust and ideal for high-pressure or corrosive environments. Their durable construction ensures long-term reliability in demanding conditions.

Share