Nov . 17, 2024 08:03 Back to list

Innovative Socket Design and Durable Resilient Seat for Gate Valve Applications

The Importance of Socket and Resilient Seat Gate Valves in Modern Applications

Socket and resilient seat gate valves are critical components in various industrial applications, providing reliable control of fluid flow. These valves are designed to meet the demands of modern piping systems, which require not only efficiency but also resilience and longevity in challenging environments.

A socket gate valve is characterized by its installation method, which involves a socket welding process. This type of valve is typically used in high-pressure systems where robust and leak-proof connections are essential. The socket weld design creates a sturdy joint between the valve and the pipe, minimizing the risk of leaks and ensuring seamless operation under pressure. This is particularly crucial in industries such as oil and gas, chemical processing, and water treatment, where any leak could result in significant safety hazards and financial loss.

On the other hand, resilient seat gate valves are recognized for their innovative design that includes a soft, elastic seating surface. This feature allows for better sealing performance and reduced torque, making these valves easier to operate. The resilience of the seat material allows it to adapt to minor irregularities in the valve body and piping, ensuring that even under varied temperature and pressure conditions, an effective seal is maintained. As a result, resilient seat gate valves are ideal for applications involving water supply and wastewater management, where preventing leaks is paramount.

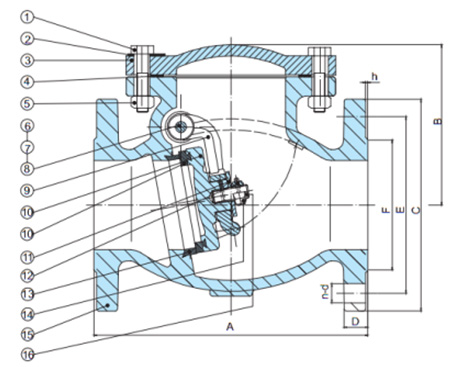

socket and resilient seat gate valve

One notable advantage of combining socket and resilient seat designs is the enhanced overall durability and longevity of the valve. Socket welding enhances structural integrity, while the resilient seat minimizes wear and tear over time. This synergy is particularly beneficial in installations where regular maintenance is challenging, as it reduces the need for frequent replacements.

Maintaining efficiency while minimizing downtime is crucial in today's fast-paced industrial environment. The use of socket and resilient seat gate valves contributes significantly to operational reliability. These valves are engineered for high performance, allowing industries to achieve optimal flow control with minimal energy consumption. Furthermore, their ease of installation and maintenance leads to substantial cost savings over the valve's lifespan.

In conclusion, socket and resilient seat gate valves are integral to modern fluid control systems. Their design offers unparalleled advantages in terms of durability, leak prevention, and operational efficiency. As industries continue to evolve and face new challenges, the advancement and application of these valves will play a vital role in ensuring the safety and reliability of fluid transport systems worldwide. Investing in high-quality socket and resilient seat gate valves is a strategic decision for any operation aiming to enhance its performance.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025