Des . 10, 2024 03:49 Back to list

Understanding Butterfly Valve Types for Optimal Lug Installation and Performance

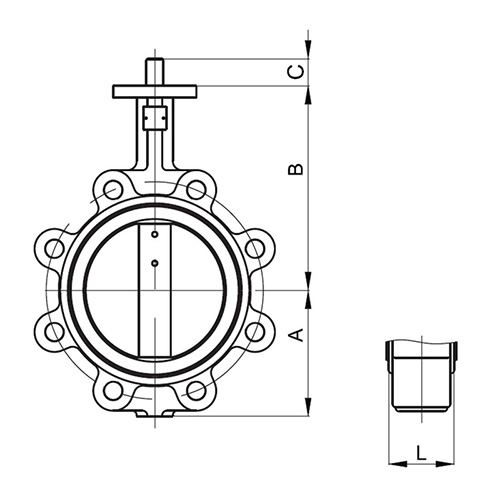

Understanding Lug Type Butterfly Valves

Butterfly valves are among the most widely used flow control devices in various industrial applications. They are known for their simplicity, reliability, and cost-effectiveness. Among the different designs, the lug type butterfly valve stands out for its unique features that cater to specific installation needs and operational demands.

What is a Lug Type Butterfly Valve?

A lug type butterfly valve incorporates a specialized design that enables it to be installed in a piping system without requiring flanges on both sides. This valve type features lugs or threaded inserts on the valve body, which allow the valve to be bolted directly to the pipe flanges. This design is particularly advantageous for systems that may need to be maintained or replaced without disassembling adjacent piping, making it an ideal choice for various applications.

Key Features of Lug Type Butterfly Valves

1. Easy Installation The lug design facilitates a straightforward installation process. Installers can secure the valve to the valve seat on either side of the piping system while eliminating the need for additional hardware.

2. Versatile Applications Lug type butterfly valves are suitable for a wide range of applications, from water and wastewater treatment to chemical processing and HVAC systems. Their flexibility makes them an invaluable component in fluid handling systems.

3. Bidirectional Flow Control Unlike some valve types that may have a defined flow direction, lug type butterfly valves allow for bi-directional flow. This capability is crucial in applications where flow direction might change or in systems that incorporate variable flow conditions.

4. Compact Design These valves typically have a compact design, making them ideal for installations where space is limited. Their reduced size enables easier transportation and installation, providing substantial benefits in terms of labor and material costs.

lug type butterfly valve

5. Low Operating Torque The design of the butterfly plate allows these valves to provide effective flow control with low operating torque. This feature can minimize the energy required for actuation, whether it is manual or automated.

Advantages Over Other Valve Types

When compared to other valve designs, the lug type butterfly valve offers several advantages. For instance, in a scenario where flanged valves would require supports on both sides to prevent leakage, the lug design allows for more straightforward installation and maintenance.

Additionally, lug type butterfly valves excel in applications where weight is a consideration. Their lightweight design, compared to traditional gate or globe valves, can reduce overall piping system weight, making them favorable for both installations and maintenance.

Challenges and Considerations

Despite their many advantages, it is essential to consider the specific operational conditions in which lug type butterfly valves will be used. The choice of materials, sealing methods, and temperature/pressure ratings can significantly impact performance and longevity. Users should also be mindful of the fact that while these valves are suitable for various applications, they may not be the best choice for every scenario. For instance, high-pressure systems may necessitate a different type of valve altogether.

Conclusion

Lug type butterfly valves serve as an essential component in modern industry, offering a winning combination of functionality, reliability, and ease of use. Their distinctive design allows for flexible installation options while ensuring effective fluid control. As industries continue to evolve and demand efficient solutions, lug type butterfly valves are expected to play a significant role in fluid management systems across the globe. Users must, however, remain informed about their specific applications and choose the right materials and configurations to maximize their benefits.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025