Jan . 20, 2025 03:38 Back to list

Dismantling Joint

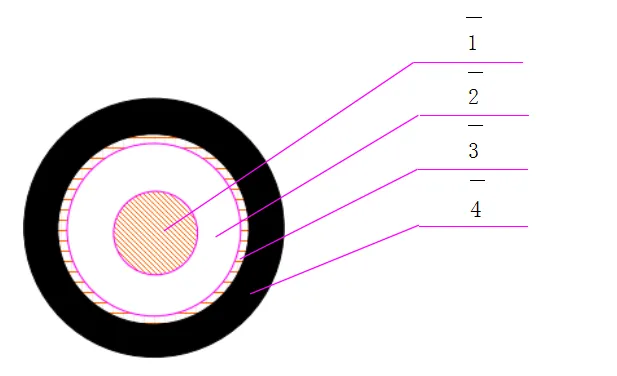

Galvanized rubber expansion joints are a crucial component in various plumbing and industrial systems, providing flexibility and vibration absorption while accommodating thermal expansion and contraction. These features are indispensable in systems subject to significant temperature variations and mechanical stress. Having spent years working with these joints, I have garnered a deep understanding of their utility and efficacy in various applications, which I'm eager to share.

Understanding the science behind these joints further reinforces their value. The rubber element serves as an elastic medium, absorbing vibrations and noise, which is advantageous in reducing wear and tear on adjoining parts. This feature significantly enhances the operational lifespan of equipment, a benefit that can't be overstated when considering the cost implications of frequent replacements. Their application isn't limited to HVAC systems alone. Galvanized rubber expansion joints are extensively used in chemical processing plants, waste treatment facilities, and even in the marine industry. Each of these sectors presents unique challenges, from handling corrosive chemicals to coping with saline water, where these joints have consistently demonstrated their resilience and adaptability. Furthermore, these joints are designed to accommodate misalignments, which inevitably occur over time due to settling or thermal cycles. Their ability to absorb these shifts without compromising system integrity underscores their importance in maintaining operational efficiency and safety. When selecting galvanized rubber expansion joints, several factors should be considered. Material compatibility with the medium being transported, temperature and pressure ratings, and movement capabilities are crucial parameters. With years in the field, I advise involving engineers during the selection process to choose a joint that precisely matches system requirements. In conclusion, galvanized rubber expansion joints are not merely components that connect sections of a pipeline; they are vital protectors that enhance system reliability, efficiency, and lifespan. Used correctly, they can save significant costs and prevent potential operational disruptions. As someone who has seen their impact firsthand, I vouch for their continued use and recommend a thoughtful approach to selecting and maintaining these indispensable components in your systems.

Understanding the science behind these joints further reinforces their value. The rubber element serves as an elastic medium, absorbing vibrations and noise, which is advantageous in reducing wear and tear on adjoining parts. This feature significantly enhances the operational lifespan of equipment, a benefit that can't be overstated when considering the cost implications of frequent replacements. Their application isn't limited to HVAC systems alone. Galvanized rubber expansion joints are extensively used in chemical processing plants, waste treatment facilities, and even in the marine industry. Each of these sectors presents unique challenges, from handling corrosive chemicals to coping with saline water, where these joints have consistently demonstrated their resilience and adaptability. Furthermore, these joints are designed to accommodate misalignments, which inevitably occur over time due to settling or thermal cycles. Their ability to absorb these shifts without compromising system integrity underscores their importance in maintaining operational efficiency and safety. When selecting galvanized rubber expansion joints, several factors should be considered. Material compatibility with the medium being transported, temperature and pressure ratings, and movement capabilities are crucial parameters. With years in the field, I advise involving engineers during the selection process to choose a joint that precisely matches system requirements. In conclusion, galvanized rubber expansion joints are not merely components that connect sections of a pipeline; they are vital protectors that enhance system reliability, efficiency, and lifespan. Used correctly, they can save significant costs and prevent potential operational disruptions. As someone who has seen their impact firsthand, I vouch for their continued use and recommend a thoughtful approach to selecting and maintaining these indispensable components in your systems.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025